Side-by-side hydraulic modular trailers with 3 files and 4 files configurations are specialized transport setups designed to accommodate exceptionally wide and heavy loads. By arranging modular trailers in parallel, these configurations create a broader and more stable platform for transporting oversized cargo. The terms 3 files and 4 files refer to the number of trailers aligned side-by-side to enhance width and load-bearing capacity.

This article overviews 3 files and 4 files hydraulic modular trailers, including their configurations, benefits, and applications in heavy-duty transport.

Table of Contents

ToggleIntroduction to Side-by-Side Hydraulic Modular Trailers

Hydraulic modular trailers are engineered for transporting heavy and oversized loads, equipped with hydraulic suspension systems that maintain balance and distribute weight evenly. Side-by-side configurations take this a step further by aligning trailers in parallel, enabling the safe transport of wider cargo.

Key Features of Hydraulic Modular Trailers

- Hydraulic Suspension: Allows height adjustability for stable, balanced transport.

- Modular Design: Trailer units can be combined to meet specific load requirements.

- High Load Capacity: Designed to handle weights that exceed the capabilities of standard trailers.

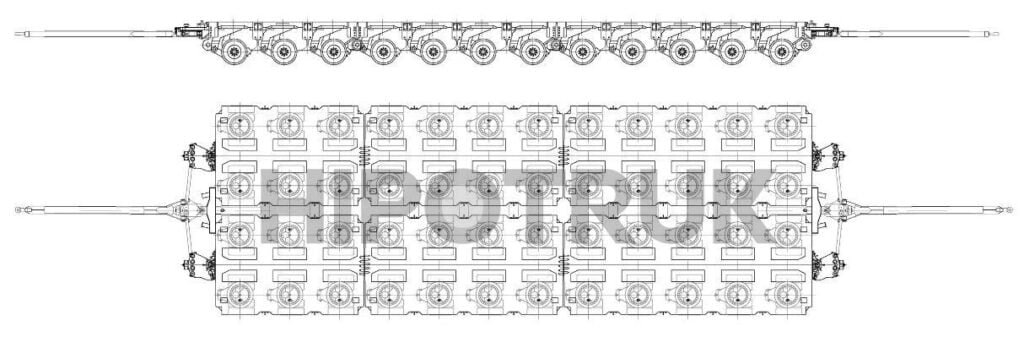

Side-by-Side Combinations Explained

According to CHINA HIPOTRUK, there are three main side-by-side configurations for hydraulic modular trailers:

- Standard (2 File): A single-width setup, approximately 2,990 mm wide, suitable for moderately wide cargo.

- Split (3 File Parallel Combination): Also known as the 3 files or one-and-a-half width configuration, measuring around 4,890 mm wide. This setup balances width and maneuverability.

- Side-by-Side (4 File Parallel Combination): The 4 files or double-width configuration, extending to approximately 6,290 mm, designed for the widest and heaviest loads.

Overview of 3 Files and 4 Files Hydraulic Modular Trailers

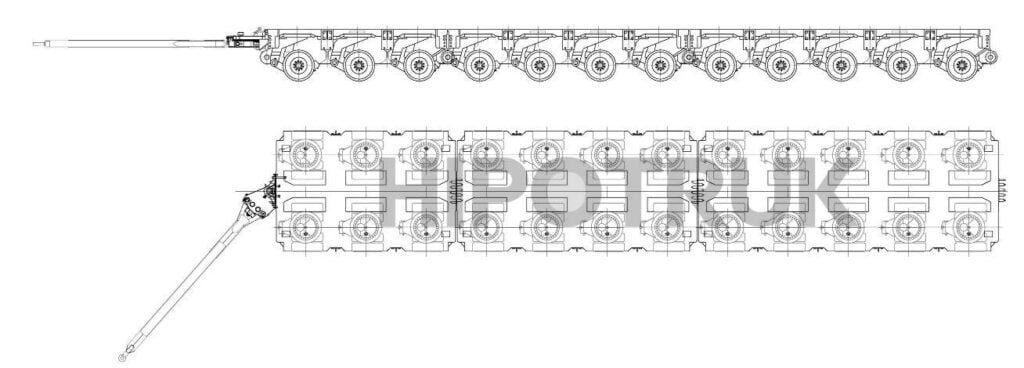

3 Files Hydraulic Modular Trailer

The 3 files configuration, also called the split or one-and-a-half width, involves three trailers placed in parallel, resulting in a width of around 4,890 mm. This setup is ideal for cargo that is wider than standard loads but does not require the full width of a double configuration.

- Purpose: Suitable for loads that need increased width without the bulk of a full double-width trailer.

- Width: Approximately 4,810 mm.

- Benefit: Provides a balance between width and maneuverability, stabilizing moderately wide loads.

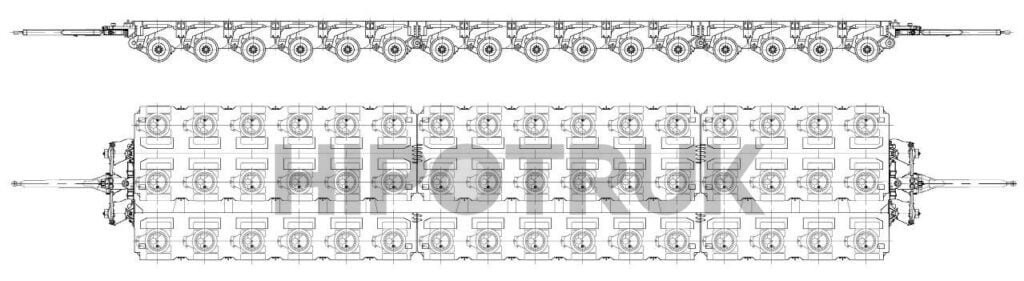

4 Files Hydraulic Modular Trailer

The 4 file configuration, also known as the side-by-side or double-width setup, combines four trailers in parallel, extending the width to around 6,290 mm. This arrangement is used for transporting exceptionally wide or heavy loads.

- Purpose: Ideal for the heaviest and widest loads, offering maximum load-bearing capacity and stability.

- Width: Extends to about 6,290 mm.

- Benefit: Provides superior stability and load capacity for large cargo, making it suitable for the most challenging transport tasks.

Key Benefits of Side-by-Side 3 Files and 4 Files Hydraulic Modular Trailers

Side-by-side configurations offer various advantages for heavy transport, making them essential for safely and effectively transporting wide and heavy loads.

1. Increased Load Capacity

Combining multiple trailer units in a side-by-side configuration significantly enhances the load-bearing capacity, allowing transport of cargo that single trailers cannot support.

- Load Distribution: The side-by-side arrangement spreads the weight across multiple trailers, reducing axle stress and increasing overall capacity.

2. Enhanced Stability for High-Center-of-Gravity Loads

Wider configurations provide a more stable base, reducing the risk of tipping and enhancing control during transport.

- Broader Platform: Offers stability for loads with high centers of gravity or unusual dimensions.

- Independent Steering: Hydraulic systems in each trailer allow independent control of axles, improving maneuverability.

3. Versatility for Diverse Transport Needs

Both 3 files and 4 files configurations are adaptable, allowing operators to choose the width that best suits the specific cargo requirements.

- 3 Files (One-and-a-Half Width): Ideal for moderately wide loads that need some additional support without the full double width.

- 4 Files (Double Width): Provides maximum width and stability for exceptionally large and heavy loads.

4. Customizable for Complex Transport Configurations

Side-by-side trailers can be customized with various accessories to enhance their functionality:

- Telescopic Widening Systems: Allow trailers to widen further for additional stability.

- Compatibility with Accessories: Can incorporate goosenecks, drop decks, spacers, and high girder bridges, enhancing versatility for complex transport tasks.

5. Improved Safety and Route Flexibility

The wider base created by the side-by-side setup improves transport safety, especially for oversized loads.

- Enhanced Safety: The configuration minimizes the risk of tipping, ensuring a safer transport process for high-center-of-gravity loads.

- Route Flexibility: While wider, the independent steering and hydraulic controls allow these trailers to navigate many routes that standard oversized transport cannot manage.

Applications of 3 Files and 4 Files Side-by-Side Hydraulic Modular Trailers

Side-by-side 3 files and 4 files hydraulic modular trailers are commonly used in industries that require the transportation of wide, heavy, or high-center-of-gravity cargo.

- Construction and Infrastructure

- Bridge Components: Moving wide bridge sections, prefabricated structures, and other infrastructure elements.

- Steel Beams: Transporting long steel beams used in large-scale construction projects where stability is essential.

- Industrial Equipment

- Heavy Machinery: Suitable for moving large, high-center-of-gravity machinery, such as transformers and power generators.

- Refinery Components: Transporting oversized equipment used in refineries and other industrial facilities.

- Energy Sector

- Wind Turbine Components: Moving wide turbine blades and tower sections that require a stable, broad base.

- Power Generators: Transporting large generators and other power distribution units.

Choosing Between 3 Files and 4 Files Configurations

Selecting the optimal configuration depends on factors such as load width, weight, stability requirements, and route limitations.

- Assess Load Width and Weight: For moderately wide loads, the 3 files configuration is sufficient, while the 4 files setup is ideal for exceptionally wide and heavy loads requiring maximum stability.

- Evaluate Stability Needs: If the load has a high center of gravity or unique dimensions, the 4 files configuration offers the most stable base to prevent tipping.

- Consider Route Constraints: Confirm that the chosen width configuration aligns with the transport route’s limitations. While side-by-side trailers provide increased stability, they must also be able to navigate the intended path.

- Explore Customization Options: Both 3 files and 4 files configurations allow additional features, such as telescopic widening or accessories like spacers, to meet specific load requirements.

Summary: The Role of Side-by-Side 3 Files and 4 Files Hydraulic Modular Trailers

Side-by-side 3 files and 4 files hydraulic modular trailers provide a safe, efficient, and versatile solution for transporting oversized loads with unique width and stability needs. By combining modular trailers in parallel, these configurations offer a robust platform for handling heavy cargo across various industries.

Key Takeaways

- 3 Files Configuration: One-and-a-half width (around 4,810 mm) for moderately wide loads, balancing width and maneuverability.

- 4 Files Configuration: Double width (around 6,290 mm) for exceptionally wide loads, providing maximum stability and load-bearing capacity.

- Enhanced Safety and Control: Side-by-side setups create a stable platform, minimizing tipping risks for high-center-of-gravity cargo.

- Customizable and Versatile: Compatible with various accessories, allowing flexibility for complex transport needs.

For companies needing to transport oversized or overweight cargo, side-by-side hydraulic modular trailers with 3 files and 4 files configurations offer an adaptable and reliable solution to meet the most demanding heavy-haul requirements.