Hydraulic Modular Trailers (HMTs) are designed to carry heavy and oversized cargo that conventional trailers can’t handle. Each component plays a crucial role in the stability, adaptability, and maneuverability of an HMT across difficult routes and terrains. Here is a breakdown on the main components that make HMTs capable of handling complex transport tasks.

Table of Contents

Toggle1. Frame

The frame of a hydraulic trailer is its backbone, providing it with the strength and stability required to transport heavy or oversized cargo safely.

High-Strength-Steel

The frame is made of high-strength steel Q690 or Q550, which makes it durable and able to handle heavy loads without warping or bending. The trailer will be able to handle long-distance transport thanks to the choice of material.

Box-Type Structure

A box-type structure is often used in the frame. This provides additional stability and distributes the weight evenly throughout the trailer. This design helps to keep the trailer in balance and reduces stress on certain points. It is safer when carrying heavy loads.

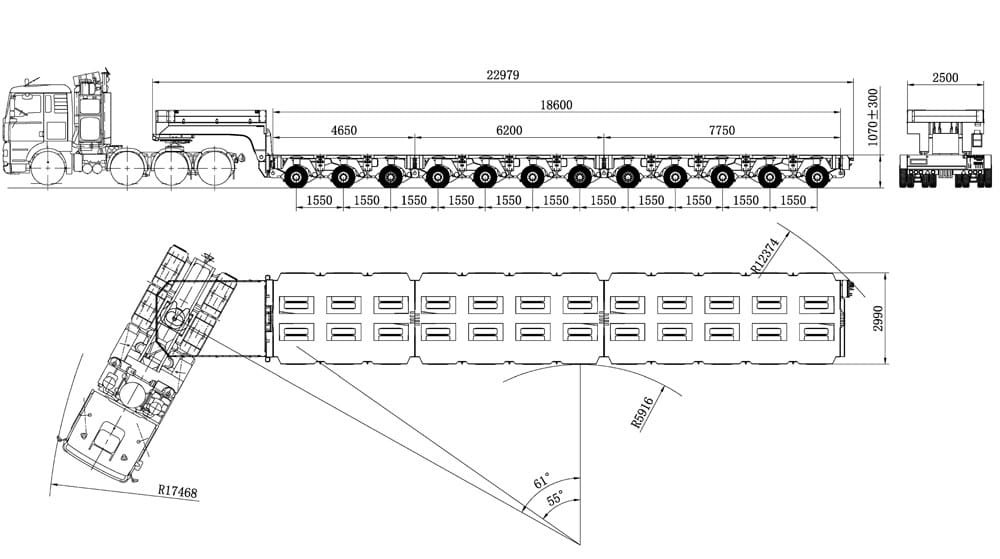

Modular Design

The ability to connect several frames is one of the most unique features of hydraulic trailers. Frames can be connected end-to-end to accommodate longer loads or side-by side for larger loads. Operators can customize the size of the trailer based on cargo.

Supports other components

The frame provides mounting points for parts such as the hydraulic suspension system, steering system, wheel bogies, etc. These connections help to ensure the trailer is stable and controlled while in transit.

The frame is a foundation for a hydraulic trailer. Its robust construction, modular design and stable design support the safe and efficient transportation of heavy cargo over challenging routes.

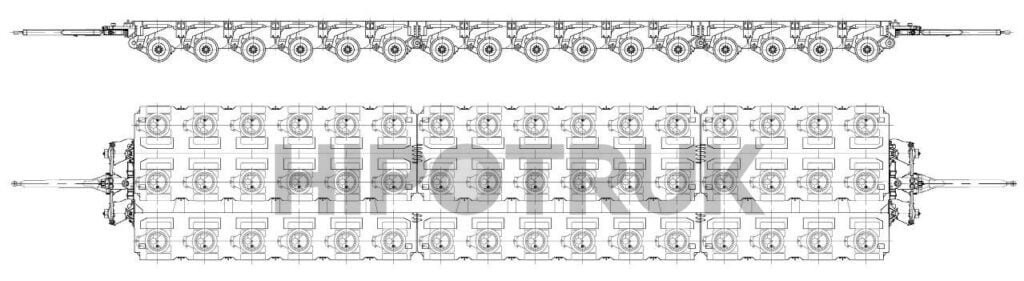

2. Hydraulic Wheel Bogie

The hydraulic wheel bogie is vital in a hydraulic modular truck (HMT) by ensuring weight balance and stability, particularly on rough or uneven terrain. The hydraulic wheel bogie distributes the weight evenly over all axles. This allows the trailer to adapt to various surfaces while keeping the cargo safe.

Key Components

Bogie Frame

The Bogie frame provides structural support for the entire wheel bogie. It holds each axle, tire and hydraulic cylinder securely. The frame is built to handle heavy loads.

Hydraulic Cylinder

Each axle is equipped with a hydraulic cylinder which can be adjusted independently. This allows the trailer to remain level on uneven terrain. This feature is crucial for stability, particularly when transporting heavy loads.

Tire and axle

Heavy-duty tires are used to support heavy loads and the axle and tire together ensure that the trailer is stable and grounded. This arrangement keeps the trailer grounded and stable.

Rocker Arms

The rocker arms allow controlled movement of each wheel, which absorbs shocks caused by rough roads. This prevents sudden impacts from affecting the cargo and results in a smoother journey.

Function

The main purpose of the hydraulic wheel bogie is to adjust the trailer for different terrains. It does this by adjusting the height of each axle, which keeps the load level and balanced. The bogie also protects the trailer from potholes and bumps by absorbing shocks. The bogie distributes weight evenly to reduce stress on the individual axles. This enhances stability and prevents mechanical issues.

3. Steering System

The hydraulic modular trailer’s steering system is designed to provide precise control. This allows operators to navigate large and heavy loads along tight and difficult routes. This system is crucial when transporting large cargo as it allows the trailer to navigate tight spaces without compromising its stability.

Different types of steering systems

Ball Bearing Race Ring

This steering mechanism is perfect for off-road applications where a more flexible turning is needed. The ball-bearing race rings allow the trailer wheels to turn with minimal resistance. This makes it easier to navigate rough terrain or uneven terrain.

Pivot Bearing System

The pivot bearing system is commonly used on heavy-duty vehicles that travel on the road. It provides a smoother and more controlled movement. It is designed for routes requiring precision steering and stability such as in urban areas or industrial sites.

Key Features

Wide Steering Angle

Hydraulic Modular Trailers offer a wide steering angle of 45 to 55 degrees. The wide turning angle of the trailer allows it to turn sharply, even when carrying heavy loads. This helps it navigate complex routes or tight spaces.

Independent Axle control

Each axle of the trailer steering system can operate independently. The operator can control every axle’s angle independently, allowing for precise movements and reducing the turning radius. The independent axle control is handy when moving oversized loads around obstacles or through narrow passages.

Steering Mechanisms

The steering system comprises central control panels, orifice plates, and hydraulic cylinders, which work together to steer every axle. These mechanisms allow for smooth and responsive steering. The operator can make adjustments in real-time.

A hydraulic modular trailer with an advanced steering system allows for exceptional maneuverability. This makes it possible to transport large cargo through complex and constrained paths safely. This level of control ensures that the trailer can handle challenging routes and provides stability and precision at every turn.

4. Power Pack Unit

Power Pack Units (PPUs) are the heart of the hydraulic system on a hydraulic module trailer (HMT). They provide the hydraulic pressure required to operate the trailer’s essential functions. This unit is responsible for steering, suspension and platform height adjustments. It’s vital to maintaining control, adaptability and stability during transport. The PPU centralizes hydraulic power to allow operators to control the trailer systems in real-time, adapting to changes in terrain, load or road conditions.

Power Pack Unit: Key Components

Engine

The engine (typically diesel or petrol) drives the hydraulic pumps, providing the power required to generate hydraulic pressure. Diesel engines are used in heavy-duty applications because of their reliability and efficiency. The engine’s power output directly impacts the PPU’s capability to maintain constant hydraulic pressure. This ensures that all functions operate smoothly.

Hydraulic pump

The hydraulic pumps is responsible for the creation of hydraulic pressure which powers the trailer’s critical systems. The pump converts mechanical energy from the motor into hydraulic energy. This allows the PPU deliver constant pressure.

Control Systems

PPU control systems enable operators to control hydraulic functions via a central control panel. These systems allow the operator to react quickly to changes in terrain or weight shifts. The control panel is easy to use and allows operators to make adjustments without disrupting the transport process.

Power Pack Unit: Function

This centralized hydraulic system is designed to provide power for all trailer functions. This central hydraulic system allows:

Steering Control

The PPU provides hydraulic pressure to the steering system, allowing independent control over each wheel. This precision control is essential for maneuvering in tight spaces and complex routes. It allows real-time changes to the direction of the trailer.

Suspension and Height Adjustment

PPU controls the hydraulic suspension system and allows for independent height adjustment of each axle. This feature is essential for adapting to uneven terrain, as it keeps the trailer level and load balanced. The height adjustment feature is useful during loading and unloading. It allows the trailer to be raised or lowered as required.

Load distribution

Controlling the suspension system, the PPU ensures the weight is evenly distributed across all axles. The PPU balances the load to reduce stress at specific points on the trailer. This will help prevent mechanical problems and improve overall stability.

Power Pack Units: Importance

PPUs are essential for the safe, efficient, and reliable operation of a modular hydraulic trailer. The PPU’s ability to maintain a constant hydraulic pressure, and its centralized control allows the trailer to adjust to changes in terrain and load dynamically. The PPU is essential for key hydraulic functions such as steering, suspension and height adjustment. Without it, these would be impossible. This would reduce the trailer’s stability and maneuverability.

The Power Pack Unit, in summary, is at the core of the hydraulic modular system. It provides smooth control and adaptability by powering the essential systems.

5. Hydraulic System

The hydraulic system plays a crucial role in the hydraulic modular trailer. It is responsible for providing power to control key trailer functions such as steering, suspension, and platform height adjustments. Working in conjunction with the Power Pack Unit, the hydraulic system ensures hydraulic pressure on demand. This allows the trailer to adapt in real-time to terrain, load conditions and transport challenges.

Hydraulic System Components

Hydraulic Cylinders and Pumps

The PPU powers the hydraulic pump, generating hydraulic pressure for the trailer’s various functions. At each axle are hydraulic cylinders that allow for suspension and height adjustment. Hydraulic pumps and cylinders provide the force required to lift, lower, and steer the trailer. This allows it to react dynamically to changing terrain and load requirements.

Valves

Valves regulate fluid flow throughout the hydraulic system, maintaining a controlled pressure for each function. These valves direct fluid into specific areas on the trailer such as the steering or suspension systems. Fluid flow control is crucial for accurate and smooth adjustments.

Hydraulic fluid reservoirs

These reservoirs hold the hydraulic fluid which flows through the system. They maintain a constant flow to ensure that the system operates without interruption. Filters are installed in the reservoirs to ensure the hydraulic fluid is clean and contaminant-free. This helps extend the life expectancy of the hydraulic components, and ensures reliable operation.

Hydraulic System Functions

The hydraulic system is responsible for multiple functions on the trailer, all of which play a part in ensuring stability, balance and control. The key functions are:

Steering Control

The hydraulic system applies pressure to the steering cylinders and allows independent control of each axle. This feature allows the operator to precisely adjust the angle of each axle, which is crucial for maneuvering a trailer in tight spaces. This system is responsive and allows for real-time adjustments. It makes it possible to navigate complicated routes without compromising on stability.

Suspension system and load balance

Each axle can be raised or lowered independently by the hydraulic suspension system. This flexibility is essential when traversing uneven surfaces or slopes, as it helps to evenly distribute weight and keeps the platform at the same level. The hydraulic suspension balances the load over all axles to reduce stress and wear on the individual axles.

Platform Height Adjustment

The hydraulic system allows platform height adjustment, which is useful for loading and unloading large cargo. The height of the trailer can be adjusted by the operator to match loading docks, or any other surface. This makes it easier to move oversized loads. This capability of adjustment is beneficial to maintain compliance with road clearance standards.

Hydraulic System: Its Importance

Hydraulic modular trailers are highly adaptable and functional. The hydraulic system plays a key role in this. The hydraulic system is essential for the adaptability of a trailer. It allows it to adjust to different terrains, handle heavy loads and provide precise controls. The trailer’s versatility is enhanced by the system’s ability for real-time steering, suspension and height adjustments.

The hydraulic system, in summary, is the foundation of the HMT’s operational capabilities. It powers essential functions that allow the trailer to maintain its stability, maneuverability and load balance. This is a safe, effective and efficient solution for transporting heavy and oversized cargo in diverse environments.

6. Suspension System

It is important to have a suspension system on a hydraulic trailer. This will ensure stability and smooth load distribution. This system is essential for balancing loads, absorbing shocks and preventing excessive strain in any part of the trailer.

Type

Hydraulic suspension in HMTs is equipped with individual suspension cylinders for each axle. This allows each axle operate independently and adjust to road variations, while minimizing the impact on the overall weight balance of bumps or slopes.

Features

Independent Height Adjustment

Each axle can be raised and lowered independently using hydraulic cylinders. This allows the trailer to adapt itself to different road conditions. When crossing uneven terrain, for example, axles can adjust higher or lower in order to maintain the platform level. This is important to maintaining the stability and safety of the cargo.

Shock Absorption

The hydraulic suspension system absorbs shocks and vibrations, which reduces the risk of cargo damage. The suspension system provides protection for fragile or sensitive cargo by dampening impact. It also ensures a smoother ride. This is especially important when transporting delicate equipment.

Benefits

Improved Stability

The suspension system improves stability by distributing the weight evenly over all axles, and adapting the suspension to the road surface. This reduces the risk of the trailer tipping or shifting the cargo.

Improved Cargo Protection

The hydraulic suspension reduces vibrations and impacts, protecting valuable or sensitive cargo from damage and ensuring that it arrives safely to its destination.

Hydraulic suspension systems are essential for the HMT’s balance, stability and cargo protection.

7. Brake System

Hydraulic modular trailers must have a reliable brake system, given the heavy loads they carry. The brake system must be able to handle the increased stopping force required for heavy-duty application, so that the trailer is able to come down smoothly and controllably even when under heavy load.

HMTs use compressed air brakes, which provide a powerful and consistent braking power. This system has advanced safety features that improve control and responsiveness, especially when the trailer is navigating hills or coming to a halt.

Components

Brake Chambers

Double and single brake chambers are used to provide the necessary braking force for slowing or stopping the trailer. Single brake chambers can be used to provide additional stopping power, particularly under heavy loads.

Relay Valves and Anti-locking Braking System (ABS)

Relay vales regulate air pressure for fast and responsive brakes. The ABS helps prevent wheel lockup, particularly during sudden stops and on slippery surfaces. This reduces the risk of sliding, while improving overall control.

Brake Drums & Air Reservoirs

Brake drums are used to apply pressure on the wheels of the trailer, and air reservoirs ensure that there is enough pressure when braking is needed. This system provides reliable and consistent braking, which is important for long descents or steep ones.

Benefits

Enhanced Control and stability

The brake system provides controlled deceleration even when the vehicle is carrying heavy loads. It maintains stability by providing powerful and smooth braking. This prevents cargo from shifting or jolting.

Safety in Heavy Transport

Advanced safety features such as ABS and valves relays ensure that the trailer is able to respond quickly to brake demands. This reduces the risk of accidents, and protects both the cargo and the surrounding traffic.

The brake system in hydraulic modular trailers is an essential component, as it provides reliable stopping power and control. It also ensures stability, which are all important for heavy transport.

8. Combination System

Combination systems enable hydraulic modular trailers to be modular. This system allows operators the ability to connect multiple trailer units, and configure them according to the specific requirements of cargo. Combination systems are essential to create a custom platform, allowing HMTs to adapt to loads with different shapes and sizes.

Function

The combination system enables trailers to either be connected side-by-side for wider loads or end-toend for longer loads. This flexibility allows the trailer to handle oversized cargo, by creating a platform which perfectly matches the dimensions of the load. It also ensures stability and balance.

Components

Hydraulic link-pins

These pins are used for securing the connection between modules. They ensure a reliable and stable link during transportation. The hydraulic link-pins can be easily engaged and disengaged, allowing quick changes in the trailer configuration.

Fast Coupling connectors

These connectors allow rapid connection of brake and hydraulic pipelines between modules. This allows seamless integration of hydraulic systems and braking across multiple units. This feature ensures hydraulic functions and brakes work in sync between all modules connected.

Combination systems allow you to configure the trailer according to your load requirements. This offers a customized solution for diverse transport needs that improves safety and stability.

9. Lifting System

The hydraulic modular trailer’s lifting system adjusts the platform height. This is important for loading and unloading as well as navigating uneven surfaces. This feature increases the adaptability of the trailer, as it allows for different road and cargo conditions.

The range is typically 300mm (+/-150mm). The range allows the trailer to be raised or lowered to match loading docks, road clearances or uneven surfaces.

Purpose

Loading/Unloading

The height adjustment allows for easier loading or unloading of heavy cargo. The trailer can be lowered down to the ground or aligned to platforms, which reduces the need for lifting equipment.

Adaptability for Terrain

The lifting system allows the axle height to be adjusted when driving on uneven terrain. This helps the trailer keep a flat platform and reduces the risk of shifting cargo.

The lifting system provides an additional layer of adaptability to the trailer, allowing it to respond to different road and loading conditions. This is essential for a safe and efficient transportation.

10. Tires and wheels

Tires and wheels on a hydraulic trailer are designed to provide traction and support heavy loads. These components need to be resilient and durable in order to support the weight of the trailer as well as its cargo. This is especially true when transporting heavy or oversized loads.

HMTs usually use tires with heavy-duty specifications, like 215/75R17.5PR16 or other similar specifications. These tires are designed to withstand the high pressures, stresses and strains associated with heavy cargo transportation. They provide stability and support on diverse terrains.

Tires and wheels that are designed for trailers can ensure the trailer is able to handle heavy loads and maintain traction, regardless of whether it’s on paved road, construction site, or uneven terrain.

11. Electrical System

Electrical systems in hydraulic

modular trailers power essential functions such as lighting, controls and interfaces. This system provides visibility and control for the operator, ensuring the trailer runs safely and efficiently.

Features

Heavy-Duty connectors

The electrical systems includes heavy-duty plugs and sockets which provide power to different parts of the trailer such as the lights and control panel. These connectors have been designed to withstand heavy-duty transport and provide a consistent power supply.

Control Interfaces

This system is integrated with control panels that allow operators to manage trailer functions and lighting precisely. It is vital for safe operation of the trailer, particularly at night or in low visibility conditions.

Electrical systems are critical to ensuring safety, visibility and allowing operators to monitor and operate trailer functions with precision.

12. Drawbar or Gooseneck

The drawbar or gooseneck is the mechanism used to connect the hydraulic modular trailer with the towing vehicle. This component is crucial for ensuring balance, evenly distributing the load, and stable towing during long-distance transportation.

Gooseneck

When used in semi-trailer setups, goosenecks provide enhanced stability by transferring a portion of the load to the towing vehicle. This design provides a better weight distribution for heavy loads and improves maneuverability when turning.

Drawbar

The drawbar is often used to tow a full trailer without having to transfer the load weight from the towing vehicle. This allows for flexibility in shorter transport distances, or industrial applications that don’t require load transfer.

The drawbar and gooseneck are both essential components to ensure that the trailer is balanced and controlled during the entire journey.

Conclusion

Hydraulic modular trailers comprise several main components, including the frame, hydraulic wheel bogies, steering system, (PPU), suspension, brake system and combination system. These all work together to provide a reliable and versatile transport solution. Each component has been carefully designed to meet the most demanding transport requirements, providing stability, flexibility, and control when transporting heavy and oversized cargo over various terrains.

Hydraulic modular trailers can be essential for industries that need precision and durability when it comes to heavy transport. Understanding each component allows us to appreciate the unmatched flexibility and performance of these trailers, making them the preferred choice in complex heavy-hauling applications worldwide.