In this guide, we will discuss hydraulic modular trailers, also known as hydraulic multi axle modular trailers, multi-axle trailers, hydraulic platform trailer and heavy-duty modular trailer. You’ll learn about these powerful transporters’ primary uses, specs, and designs. Moreover, we’ll cover the main components and different combination forms of hydraulic modular trailers.

By the end of this section, you’ll also discover the forecast for modular transporters in China and how to select a reliable supplier. Let’s begin by defining and describing the modular trailer.

Table of Contents

ToggleWhat is a Hydraulic Modular Trailer?

A hydraulic modular trailer is a series of special vehicles used to transport large, difficult-to-disassemble cargo and over-length goods. These versatile trailers find applications in power stations, the chemical industry, the iron and steel industry, and construction. Additionally, modular trailers are ideal for mining operations due to their excellent lateral stability.

Modular Trailers vs. Self-Propelled Modular Transporters (SPMT)

A self-propelled modular transporter (SPMT) without a power pack unit is similar to a hydraulic modular trailer. However, there are two main differences between them:

- Steering system: Modular trailers use a mechanical steering system, while SPMTs have a different steering system.

- Combination options: Modular trailers can be combined using a gooseneck and a drawbar, unlike SPMTs.

Key Features of Modular Trailers

Balanced Vehicle Loading Platform

Thanks to its excellent damping property, the vehicle loading platform of a modular trailer maintains balance when transporting goods on rough or bumpy roads. The brace kit can achieve three or four brace points, ensuring uniform load distribution and preventing partial sets.

Hydraulic Steering System

Modular trailers feature a hydraulic planar pitman driver in their steering system. The vehicle can achieve a minimum turning diameter and regular drive by adjusting the hydraulic steering system and using different reasonable pitman layouts.

Robust Construction

The trailer’s supporting assemblies have a solid box beam structure. The main frame, the longitudinal girder, bogie frame, steering arm, and platform, are made of high-performance welding steel.

Towing Modes and Speed

Series modular trailers have two primary modes: full-trailer towing and semi-trailer towing.

- Full-trailer towing mode:

- Maximum speed: 40 km/h

- Achieves maximum tractive force

- Used for heavy-duty transportation at low speeds

- Semi-trailer towing mode:

- Reduces vehicle length and minimizes turning diameter

- Increases effective load and speed

- Maximum speed: 80 km/h (twice the speed of full-trailer towing mode)

Chapter Two: The Specs and Dimensions of Modular Trailers

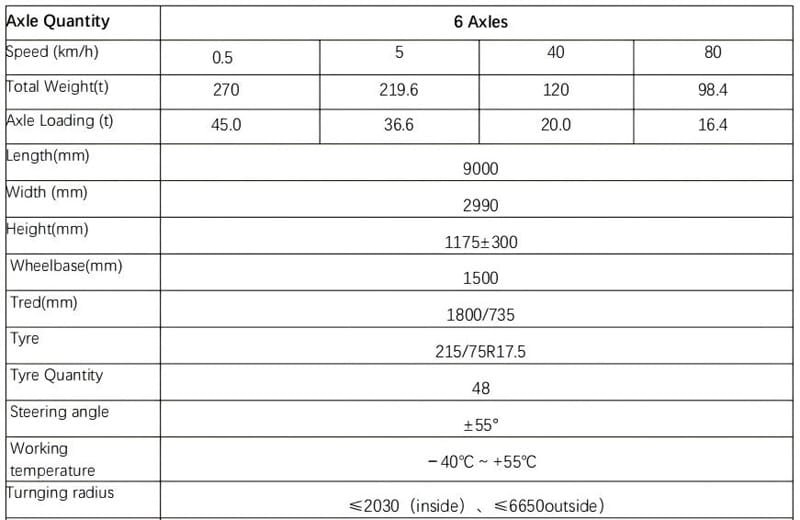

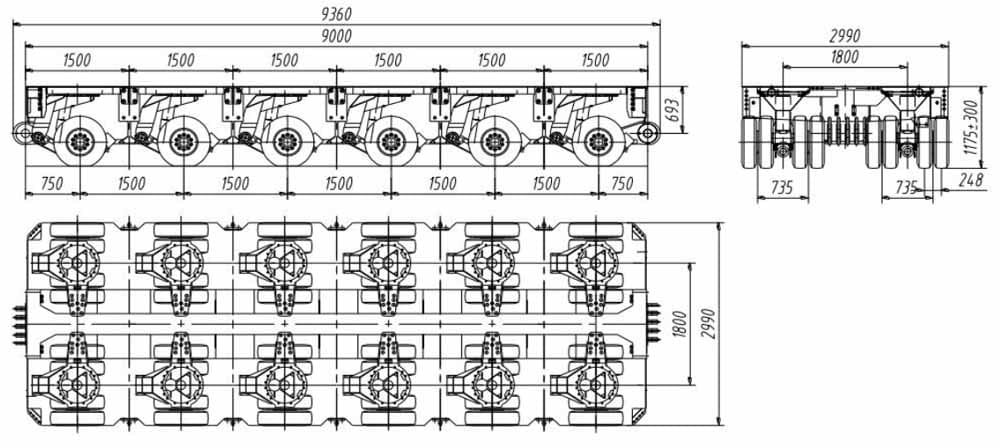

The Hydraulic Modular trailers come in different units, including 2, 3, 4, 5, 6, and 8-axle models. The maximum load per axle can reach up to 45 tons. As the number of axle lines increases, so does the hydraulic modular trailer’s loading capacity.

Half Modular Unit

The framework of all the axles in a half modular unit is combined by the left and right half modular units. Notably, the technical parameters of the half-modular unit are the same as those of the modular unit after combination.

It’s important to note that the left and right half modular units cannot be used independently. These units can only be utilized when combined or when they are combined with the modular unit.

In the next chapter, we will delve into the main components of a modular trailer, providing detailed specifications, structures, and functions of each piece of equipment. Additionally, we’ll explore the additional accessories that come with these versatile transporters, enhancing their adaptability to various applications.

Chapter Three: Illumination of Main Equipment

This chapter outlines the main components of a hydraulic modular trailer. We’ll discuss the specifications, including the structure and functions of each component or equipment. By the end of the chapter, you’ll also learn about the additional accessories that come with hydraulic modular trailers.

3.1 Frame

The main girder of the frame has a box-type carrying beam structure. High-performance welding steel ensures stability and reliability. The frame’s surface requires treatment, such as sandblasting, and the painting thickness should meet national standards.

The painting brand used should be among the top brands in the world. All the small-sized parts of the frame should be zinc-plated. The box-shaped center beam and stable crossbeams give the frame a high degree of rigidity, allowing it to achieve its optimal loading level.

The steering system, air tank, and hydraulic oil tank are all integrated into the bogie frame, protecting the parts against damage and corrosion. The frame has a reinforced loading deck, which allows extreme point loads. The optimized bolt-plate coupling eliminates any problems that may arise when assembling longitudinal combinations.

3.2 Hydraulic Wheel Bogie

The modular unit uses a hydraulic wheel bogie consisting of a bogie frame, hydraulic cylinder, axle, tire, and rocker’s arm. It has a strong load capacity. When the road is uneven in the transverse direction, the axle swings to compensate.

If the road is uneven in the driving direction, the hydraulic lifting system adjusts the modular supporting system. The modular unit can assume a 3-point or 4-point supporting system to ensure that each supporting point carries an even load.

3.3 The Mechanism of Steering

The steering mechanism comprises the steering central panel, steering orifice plate, steering cylinders, and steering rods. The steering orifice plate is welded to the bogie frame and has specific quantities of assembling holes used to install steering rods.

The positions where steering rods are installed on the steering orifice plate can be changed to suit different combination modes of the modular unit. The unit can meet the minimum steering radius and the maximum turning angle of 55 degrees.

The modular unit uses three major steering modes:

- All-wheel steering along (over five axle lines)

- Diagonal steering along

- Front-wheel steering mode

The steering rods can be adjusted quickly and easily to suit the desired steering angle. The modular has a hydro-mechanical all-wheel system with a two-circuit system, ensuring that the steering system maintains its functionality even when one or more steering circuits fail.

Hydraulic modular trailers have two types of wheel bogie steering systems:

- Ball bearing race ring

- Pivot bearing

Ball Bearing Race Ring

The steering system used in a modular transporter determines the types of operations and terrain that the transporter can handle. Modular transporters with ball-bearing race-ring steering systems are designed for off-road operations. These transporters can bear heavy loads within a site and are well-engineered for safe and top performance in heavy-duty operations.

Pivot Bearing

Hydraulic modular transporters with pivot bearings are designed for heavy-duty on-road transport operations. Their reinforced frames enable them to handle axle loads, making them ideal for in-plant operations.

The mechanism of steering uses two ways to steer the axles:

- Self-steering: When the tractor or truck is steering, its drawbar or gooseneck delivers a signal that makes the axles start steering simultaneously.

- A remote control or valve switch is a manual control for axle steering.

3.4 Hydraulic System

The pump in a modular transporter uses hydraulic technology, which effectively controls the driving speed. The steering and suspension pumps use the constant pressure controller to realize a quick response whenever they need steering power.

The driving motor switches between driving and following and uses a large-torque radial motor. All the hydraulic cylinders in the transporter have anti-block valves, which are important when the pipeline is broken.

3.5 Brake System

The modular unit is equipped with a compressed air brake system consisting of double and single brake chambers, relay valves, brake drums, and reservoirs. The brake system also has two brake lines that function as the service and parking brakes.

3.6 Hydraulic Suspension

The individual swing axles in a hydraulic modular trailer consist of the hydraulic suspension, which can be connected to different support circuits. The purpose of connecting the suspension to different circuits is to ensure that the axles have equal loads.

When the axles have equal loads, optimal lengthwise and crosswise leveling is guaranteed, even when driving on uneven terrain. The equal loads also regulate extreme cross-falls.

3.7 Lifting System

The modular unit’s platform’s total lifting length is 600mm. The platform provides a compensation of ±300mm, which is enough for the axial load. The suspension cylinder is installed as the steer wheel bogie.

The two ends of the suspensions have joint bearings, which protect the cylinder from damage. The hydraulic accumulator provides good cushioning when the modular transporter is unloaded.

3.8 Combination System

All modular units can be combined side-by-side or end-by-end. A hydraulic link pin is used to combine modular units end-by-end. Combining hydraulic and brake pipelines requires fast coupling connectors with high-performance levels. The electric interfaces use a heavy connector, which is reliable.

3.9 Power Pack

The hydraulic power pack and the controlling devices of the hydraulic modular transports can perform various functions, including steering, adjusting, and maintaining the vehicle combination. The power pack is different from the PPU in its function and performance.

The power pack cannot provide the same high power as the PPU. It can only give the power to steer the modular trailer, but the power cannot drive the axles.

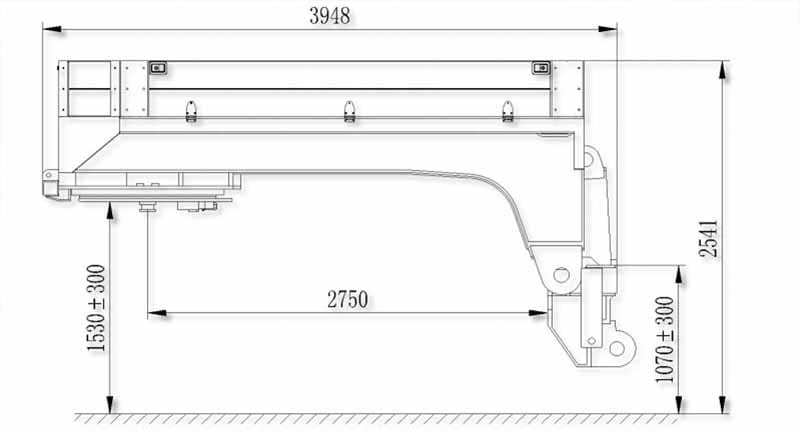

3.10 STZ-V Gooseneck

When the tractor truck is steering, the STZ-V gooseneck delivers signals that make the axles steer at the same time. The hydraulic gooseneck also has a lifting function that can adapt to the height of the cargo platform.

Sometimes, the fifth wheel and gooseneck bear part of the cargo weight. The gooseneck is considered the best alternative to the drawbar equipment. Connecting the front axle line cylinders with the gooseneck cylinders guarantees the load transfer from the axle lines to the gooseneck.

This connection eliminates the need to add more weight to the truck tractor to generate enough traction force. The ratio between the axle load and the fifth wheel load can be adjustable both hydraulically and mechanically to a wide range.

Goosenecks in modular trailers have two pairs of steering cylinders that supply the trailer’s front and rear steering systems. The coupling height and clearance of the rear gooseneck can be adapted to fit most truck tractors on the market.

3.11 Loading Equipment

The hydraulic modular trailer’s loading equipment includes drop deck beds, vessel bridges, intermediate spacers, excavator decks, extendable spacers or telescopic beams, and turntables.

Drop Deck

This drop deck has a low center of gravity for safe transport conditions because a beam construction height down to 250mm is very suitable for transporting transformers if there are height restrictions, such as under bridges or power lines. The coupling heads are firmly welded to the deck, or there is alternatively an over-drivable hook system with a quick coupling device.

Vessel Bridge

Vessel bridges are ideal for transporting higher and wider abnormal tanks, vessels, and other equipment. The length and width of the bridges can be adjustable and extendable to accommodate various equipment sizes.

Intermediate Spacer

Known as a connection platform, these spacers link multiple trailer modules to extend the overall length, particularly beneficial for long yet relatively light loads.

Extendable Spacers

Also known as telescopic beams, extendable spacers are key accessories for hydraulic modular trailers. They are designed to increase the trailer’s length, allowing it to carry longer loads.

Excavator Deck

Excavator decks on hydraulic modular trailers are specialized loading platforms designed to accommodate and transport excavators and other types of heavy construction machinery.

Turntables (Bolster)

Turntables are available for transporting long and heavy loads, such as concrete bridges, tanks, and large girders. The front turntable is a purely mechanical system, and the rear turntable is generally equipped with a hydraulic self-tracking device to steer the rear dolly automatically.

200 Ton Turntable

The 200-ton turntable is used to transport over-length goods that cannot be transported with other structures of modular transporters. As the name suggests, the turntable has a weight limit of 200 tons, meaning it cannot transport over-length goods that are above 200 tons.

The turntable should be used in pairs and on a modular combination trailer. Many modular transporters have front and rear turntables that transport long and heavy loads. The front turntable in most cases uses a purely mechanical system, while the rear turntable uses a hydraulic self-tracking device.

Depending on the requirements, the front turntable can have a 1-point or 2-point bearing. The bearing is adjusted by the removable sliding shoes. The device in the rear turntable operates the rear dolly automatically. The turntable bearings are not limited to 1-point and 2-point bearings.

You can order a customized turntable for a 3-file combination or 4-file combination trailer. Depending on your preference, the customized turntables may come with load repartition frames.

Blade Lifter (Wind Blade Adapter)

The Blade Lifter, or wind blade adapter, is ingeniously designed for transporting wind turbine blades, especially in challenging mountainous areas. Integrated with a hydraulic modular trailer or SPMT module, this system’s advanced hydraulic cylinder control and slew bearing enable the blade to tilt up to 60 degrees. This capability is vital for safely maneuvering around obstacles like trees, cliffs, buildings, and power lines, ensuring the secure and efficient transport of these colossal blades.

Wind Tower Adapter

Specifically crafted for moving windmill tower segments, the Wind Tower Adapter is a cornerstone in wind turbine logistics. It adeptly manages tower segments up to 150 tons and 6500mm in diameter when paired with hydraulic multi-axle modular trailers. This adapter plays a critical role in the secure and stable transportation of these significant turbine components.

Girder Frame

At the heart of the girder bridge trailer lies the Girder Frame, strategically placed on both the front and rear transport modules to support heavy loads. The load is “hoisted” by the frame and distributed evenly to the multi-axle transport modules at both ends, ensuring balanced load sharing. With no wheel restrictions beneath the frame, the overall transportation height can be significantly reduced, even to ground level, which is advantageous for height-sensitive transports.

The girder bridge trailer offers not only ease and safety in loading and unloading but also independence from additional lifting equipment for some models. Moreover, the split-type transporter’s flexible steering structure facilitates effortless navigation, even in tight corners and with long vehicle lengths.

3.12 Drawbar Equipment

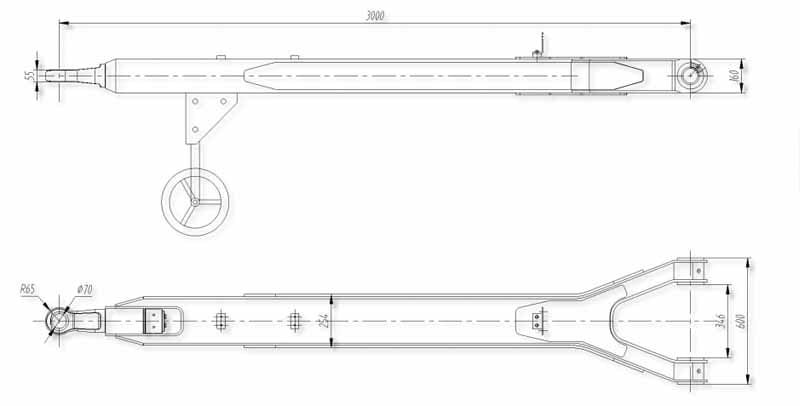

The drawbar is the main accessory in a modular transporter. The drawbar can have different dimensions, including 2.5 m, 3 m, and 5 m. A drawbar is sometimes used to pull or push a modular platform.

Transportation companies prefer modular trailers with drawbar equipment because they offer high maneuverability, even in difficult situations. Using the drawbar equipment is the easiest way to operate a modular trailer.

A modular transporter that has a drawbar on each edge can easily change the driving direction where necessary. Some manufacturers use a common rule of thumb that all trailers with more than 18 axle lines should use a drawbar system instead of the common gooseneck system.

3.13 Electric System

The modular trailer has a power pack with a rated voltage of 24 V. The equipment in the trailer that uses electronic monitoring and control has an LCD color monitor. The micro control system has a special controller whose function makes the control system of the module unit more stable and reliable.

The system also has a CAN bus that enables data transmission from one controller to another and from the controller to the displayer. The displayer has several functions, including normal monitoring and operation. It also has settings for the meter display, lighting alarm, and lighting.

The meter display shows the speed, water temperature, braking system pressure, oil pressure, and engine speed. The lighting alarm shows the hydraulic filter alarm, fuel oil lower alarm light, air pressure brake warning light, and engine oil pressure alarm light.

It also consists of the parking brake indicator, accumulator charging indicator, cooling indicator, temperature alarm, and engine filter alarm. The third function of the displayer is the lighting, which consists of the blinker, warning light, side light, and reversing light.

3.15 Additional Accessories

Hydraulic modular transporters have different accessories depending on their configuration and combination form. The different combination forms are discussed in detail in Chapter Four.

Manufacturers provide a wide range of accessories to enable users to customize their modular transporters to suit different operations. Some of the accessories that come with these transporters include goosenecks, radio controls, and hydraulic bolt couplings.

Other accessories include hydraulic power packs, steering heads, load spreaders, long-load turntables, side-by-side devices, and pulling devices. Depending on the manufacturer’s preference, the accessories are sometimes already installed in the modular trailer.

In the next chapter, we’ll explore the various combination forms of modular trailers, providing insights into how these versatile transporters can be configured to tackle different transportation challenges.

Chapter Four: Combination Forms of a Modular Trailer

The modular combination hydraulic trailer can achieve three towing forms. These forms are possible when the vehicle’s entities are connected with different combination accessories and auxiliary equipment.

The modular hydraulic trailer can realize three major combinations:

- Combination with drawbar: Includes the drawbar, vehicle entity, and side steering frame

- Combination with STZ-V gooseneck: Involves the STZ-V gooseneck and vehicle entity

- Combination form or self-towing: Achieved through a combination of the PPU device, module unit, and self-propelled module unit

The power device in the self-towing combination supports multiple functions, including hydraulic driving, an air brake system, a hydraulic lifting system, and hydraulic steering. The modular trailer with this combination can completely replace the traditional vehicle in a specific transportation environment, such as transporting overweight goods below 5km/h.

Let’s now look at the combination forms in detail.

4.1 Combination with Drawbar

This combination form is available in different series, including the 2-file, 3-file, and 4-file combination with drawbar. The main difference in these combinations is the type of accessories used.

2-File Combination with Drawbar

This combination consists of the drawbar, power pack, modular unit, side steering frame, and combination accessories. You choose the modular unit based on the type of goods you want to transport. You can get a modular unit of up to 32 axle lines. You can also choose other equipment that works with the 2-file combination with a drawbar, such as a flat beam or a low flat beam.

3-File Combination with Drawbar

The 3-file combination with drawbar comes with the drawbar, power pack, side steering frame, modular unit, combination accessories, half modular unit, central steering frame 1, and central steering frame. The components tell you that the 3-file combination is better than the 2-file combination with drawbar.

4-File Combination with Drawbar

The combination consists of a drawbar, power pack, central steering frame, modular unit or half modular unit, side steering frame, and combination accessories. For all the file combinations with drawbar forms, you can get modular units of up to 32 axle lines.

4.2 Combination Form of the Turntable

The combination form of the turntable has a drawbar, turntable, modular unit, power pack, side steering frame, and combination accessories. The varying component in this combination is the turntable. The turntable is used in pairs when the modular transporter carries over-length goods.

4.3 Combination with STZ-V Gooseneck

This combination consists of the STZ-V gooseneck, modular or half-modular unit, power pack, and combination accessories. The modular units with this combination form have up to 16 axle lines. Hence, you can choose the right modular unit for your type of goods.

The only limitation of this combination and its type of modular unit is that it may not transport over-length goods. You can also add other auxiliary equipment, such as a Extendable Spacer, to the chosen modular unit.

4.4 Pulling Work Model

Sometimes, the tractor truck does not have enough power to pull the modular trailer from one location to another. In such an instance, a PPU is added to pull the trailer.

Chapter Five: The State Of Modular Trailers In China

China’s transportation industry has been developing rapidly as manufacturers adopt the latest technology in their factories. One reason modular trailer manufacturers have been adopting new technologies is to keep up with competitors from other countries worldwide. The manufacturers have also adopted the latest technologies to avert the notion that Chinese products are low-quality.

As you shop for a modular transporter from China, you need to know the industry’s current state, outlined below.

Rapid Development in the Industry

The demand for modular transporters from China has rapidly increased in recent years. Foreign companies have dominated the market for these transporters for many years, as they have access to the best technologies to assure their clients of long-lasting and high-performance transporters. However, as manufacturers in China invest in the same technology, they have been able to guarantee that their clients receive the same high quality.

Another factor contributing to the rapid development in the industry is the high price of modular transporters from other countries. Many business owners are turning to the Chinese market for affordable yet high-quality modular transporters. Chinese suppliers also beat foreign companies in offering timely services to their clients.

Increasing Number of Suppliers

As the demand for affordable modular trailers increases, more suppliers have joined the industry. Consequently, buyers have many suppliers to choose from when exploring the Chinese market. The entry of new suppliers benefits buyers because suppliers have to offer fair prices to stay in business.

However, many suppliers still offer the same old models of modular transporters. Some suppliers still use obsolete models from foreign companies in their manufacturing processes. Such prototypes have restricted growth in the industry.

HIPOTRUK: Breaking Away from the Trend

A few suppliers, like HIPOTRUK, are breaking away from this trend by offering the latest transporter models. HIPOTRUK has modern designs of modular transporters, which are associated with higher levels of performance and efficiency. Consequently, the brand competes effectively with other brands in the global market.

HIPOTRUK’s modular trailers offer the latest technology and accessories for efficient transportation.

HIPOTRUK’s 45 Tons per Axle Load Capacity

HIPOTRUK’s latest models of transporters have a high loading capacity, with the ability to supply 45 tons per axle load. These models are compatible with German brand modular trailers.

The high axle load technology improves the technology used in three major systems:

- The structural strength of the vehicle

- Hydraulic system hoisting capacity

- Capacity of the running gear axle and tire bearing

Moreover, the HIPOTRUK modular transporter’s engine and hydraulic system use German parts, ensuring compatibility with German modular trailers, one of the top brands in the global market for heavy-duty transporters.

External Resources

To learn more about the state of modular trailers in China and the global market, consider exploring the following external resources:

- Modular Trailer Market Size to Reach $3.52 Billion by 2028 – PR Newswire

- Modular Trailer Market by Type, Payload Capacity, Application, and Region – Global Forecast to 2027 – MarketsandMarkets

- Global Modular Trailer Industry (2020 to 2027) – Market Trends and Drivers – GlobeNewswire

In conclusion, the hydraulic modular trailer industry in China is experiencing rapid growth, with manufacturers like HIPOTRUK leading the way in terms of technology and innovation. As more suppliers enter the market and competition increases, buyers can expect to find high-quality, affordable modular transporters that cater to their specific needs.

Conclusion

The knowledge of the specifications and functionality of modular trailers will help you select the best model for your company. However, you must also consider the quality standards, prices, factory strength, and technology of different suppliers.

China remains one of the best markets in which to buy a modular trailer. You can get models of modular transporters that are compatible with other international brands. If you choose the right manufacturer like HIPOTRUK, you will get a modular transporter with a firm structure and a high loading capacity.

When selecting a supplier for your modular trailer, consider the following factors:

- Quality standards: Ensure that the manufacturer adheres to strict quality control measures and uses high-quality materials in their production process.

- Competitive pricing: Compare prices from different suppliers to find the best value for your investment. However, don’t compromise on quality for a lower price.

- Factory strength: Assess the manufacturer’s production capacity, experience, and reputation in the industry. A strong factory will be able to deliver your modular trailer on time and provide reliable after-sales service.

- Technology: Look for a supplier that invests in the latest technology and continuously improves their designs. This will ensure you get a modular trailer with optimal performance and efficiency.

By considering these factors and partnering with a reputable manufacturer like HIPOTRUK, you can acquire a high-quality modular trailer that meets your specific transportation needs and provides long-lasting value for your business.

Additional Resources

To further expand your knowledge about modular trailers and make an informed decision when selecting a supplier, explore these external resources:

- What is a Hydraulic Modular Trailer – From Wikipedia

- Learn Hydraulic Modular Trailers Specifications, Designs, Applications, Components, and Combinations – From HIPOTRUK

By staying informed and working with a trusted manufacturer, you can confidently invest in a modular trailer that will help your business succeed in the competitive world of heavy-duty transportation.