Table of Contents

ToggleIntroduction

Spacers are essential components in hydraulic modular trailers, enabling flexibility, stability, and optimized load management. Moreover, spacers are vital for handling oversized cargo across industries like wind power, construction, and heavy equipment transport.

Understanding Spacers in Hydraulic Modular Trailers

Spacers are integral components in hydraulic modular trailers, designed to increase the adaptability and capacity of these trailers for transporting large, heavy, or unusually shaped loads. They are critical in enhancing the operational flexibility and safety of modular trailers used across various industries.

Purpose of Spacers

The primary function of a spacer is to extend the loading area or adjust the axle spacing on a hydraulic modular trailer. This extension enables the trailer to handle oversized loads—in terms of length and weight—by improving the load distribution across the trailer. By adding length or spacing between axles, spacers prevent undue stress on any one part of the trailer, which is essential for maintaining stability, particularly during the transport of long or heavy items such as wind turbine blades, construction beams, and large industrial machinery. Importantly, this additional capacity is achieved without needing more axles, reducing overall equipment requirements and operating costs.

For instance, a trailer outfitted with intermediate or extendable spacers can carry lengthy cargo with even weight distribution, reducing the likelihood of tipping or structural stress. In this way, spacers enhance load-handling capabilities and contribute to safer and more efficient heavy transport operations.

Compatibility of Spacers

Spacers are carefully engineered to integrate seamlessly with modular trailer systems, allowing for configuration flexibility. Given the high-stakes nature of heavy transport, most spacers are designed to be compatible with major trailer brands, such as Goldhofer, Nicolas, Cometto, and Scheuerle. This compatibility ensures that spacers can be used across various trailer systems without compromising structural integrity or safety. By choosing the right spacers for their trailers, operators gain flexibility in managing diverse cargo sizes and types, ultimately enhancing the trailer’s operational range and versatility.

Types of Spacers for Hydraulic Modular Trailers

Spacers come in several types, each tailored to specific functions and cargo requirements. The three primary types—Intermediate Spacers, Custom Spacers, and Extendable Spacers (Telescopic Beams)—are essential tools for maximizing trailer capacity, stability, and adaptability.

1. Intermediate Spacers

Intermediate spacers are among the most common and versatile spacers, primarily used to extend the trailer’s length or adjust axle spacing. This added extension enables the trailer to accommodate longer cargo, which would otherwise exceed standard trailer dimensions.

- Function: Intermediate spacers are designed to increase the loading area without requiring additional axles, effectively enhancing the trailer’s capacity for long or heavy loads. By distributing the load more evenly along the trailer’s length, these spacers help prevent axle overload, ensuring safe and stable transport.

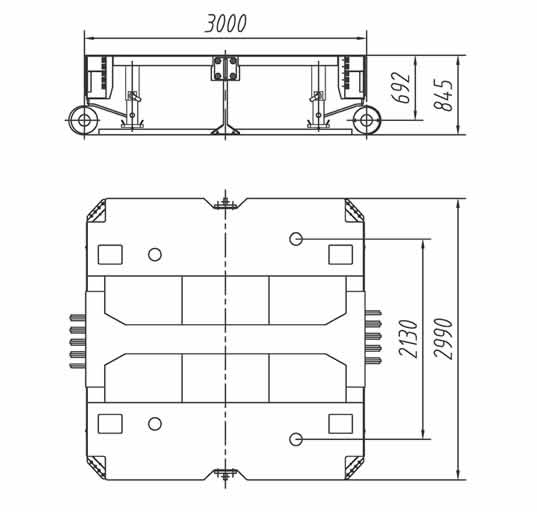

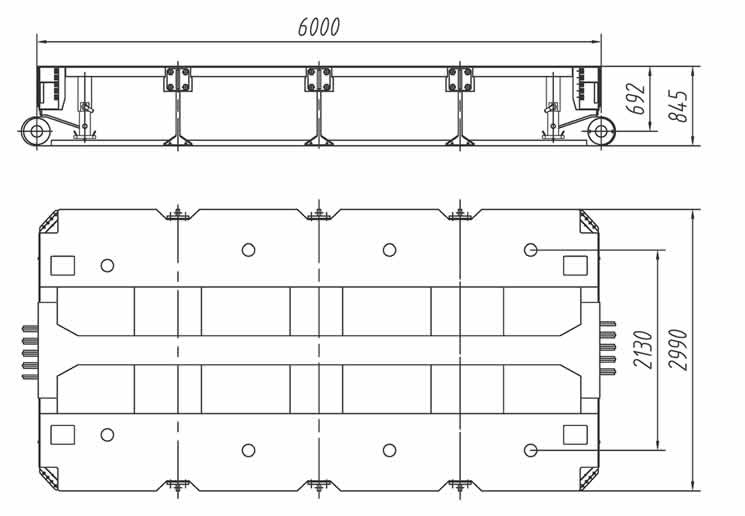

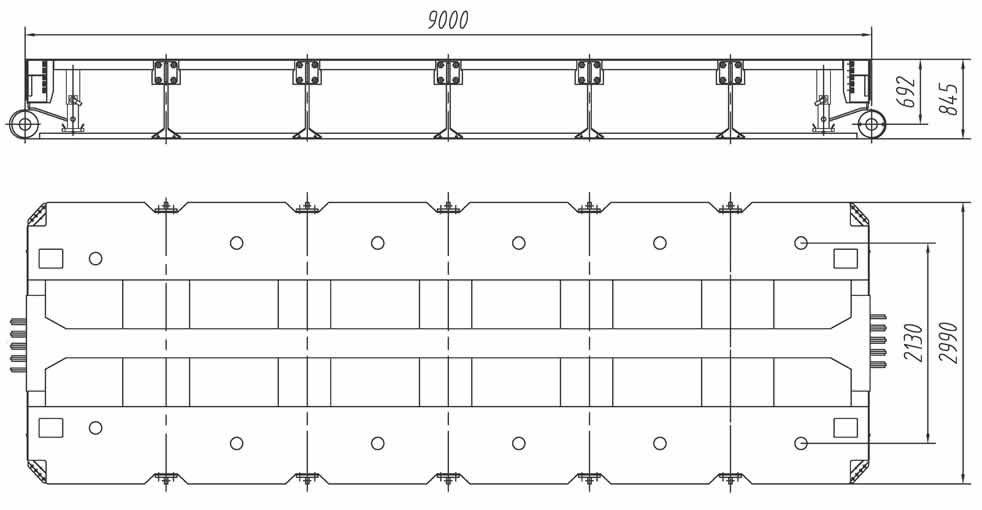

- Common Lengths: Typically available in standard lengths of 3m, 6m, and 9m, intermediate spacers offer flexible configuration options based on the cargo’s size and weight.

- Construction: Made from high-tensile steel, these spacers are capable of withstanding high bending moments and concentrated loads, making them ideal for handling large, dense cargo. The steel construction also ensures durability, as spacers must maintain their structural integrity under extreme weight and stress.

- Compatibility: Intermediate spacers are widely compatible with major modular trailer brands, including the HIPOTRUK modular trailers, Goldhofer THP/SL modules and Self-Propelled Modular Transporter (SPMT) systems. This compatibility ensures that they can be integrated into existing trailer systems without requiring extensive modifications.

2. Custom Spacers

Custom spacers are specialized spacers tailored to meet unique transport requirements. Custom spacers provide a precisely designed solution to optimize the trailer’s performance for projects with specific cargo dimensions, weight distribution needs, or special structural requirements.

- Customization: Custom spacers are designed to fit unique cargo dimensions and weight needs, offering additional length and load-bearing capacity to transport specialized items safely. They are engineered to balance specific load configurations, providing tailored support that enhances stability and prevents structural strain.

- Compatibility: Custom spacers are compatible with various modular trailer brands, including HIPOTRUK, Goldhofer, Nicolas, Cometto, and Scheuerle, making them adaptable for various heavy transport projects. Their design is carefully calibrated to ensure they fit securely and function seamlessly with these trailer systems.

- Applications: Custom spacers are frequently used for highly specialized loads that require precise configuration, such as in aerospace, industrial machinery transport, and large-scale construction projects. For example, a custom spacer may be designed to handle the unique weight distribution of a massive generator or the unusual dimensions of prefabricated construction elements.

3. Extendable Spacers (Telescopic Beams)

Extendable spacers, also known as telescopic beams, are highly adaptable spacers designed to increase the trailer’s length dynamically. These spacers provide a unique advantage for loads with variable dimensions, allowing for on-the-go adjustments to trailer length as transport needs evolve.

- Function: The primary function of extendable spacers is to adjust trailer length according to the size of the load, providing unparalleled flexibility in load configuration. These spacers are particularly useful in projects where the exact load length can vary between transports, such as when handling different sections of wind turbine blades or modular construction units.

- Integrated Features: Extendable spacers are equipped with hydraulic pipelines, enabling smooth hydraulic connections between trailer modules. This integration allows the trailer’s hydraulic circuits to function as a cohesive system, maintaining stable performance even as the trailer length changes.

- Versatility: Extendable spacers are ideal for industries where variable load sizes are common, such as wind power, construction, and heavy equipment transport. By enabling operators to adjust the trailer’s length, these spacers allow a single trailer configuration to accommodate multiple cargo sizes, which reduces the need for additional equipment and improves operational efficiency.

Extendable spacers provide a cost-effective solution for companies that regularly handle oversized loads, allowing trailers to adapt to different load requirements without compromising safety or performance.

Benefits of Using Spacers in Hydraulic Modular Trailers

- Enhanced Load Flexibility: Allows the trailer to be reconfigured to handle diverse load dimensions and weights.

- Optimized Load Management: Spacers distribute load evenly across the trailer, reducing stress on axles and improving balance.

- Increased Capacity for Oversized Cargo: Trailers can safely transport larger or longer loads without sacrificing stability.

- Cost Efficiency: Spacers allow a single modular trailer to adapt to different needs, minimizing the need for multiple trailers.

Examples from Leading Manufacturers – Goldhofer and HIPOTRUK

Goldhofer

Goldhofer provides a range of spacer solutions that work seamlessly with their hydraulic modular trailer systems to meet different transport requirements:

- Intermediate Spacers: These spacers extend the loading area or increase axle spacing without additional axle load, making them ideal for longer cargo. Standard lengths include 3m, 6m, and 9m, and they are constructed with high-tensile steel to handle significant bending moments and concentrated loads.

- Telescopic Spacers: Goldhofer’s extendable frames are accessories for hydraulic modular axles. These telescopic spacers allow longer cargo transport by reducing the number of axles needed while maintaining stability. They come with integrated hydraulic pipelines, ensuring smooth interconnection between modules. Custom sizes are available to match specific customer needs, making these spacers versatile for handling oversized loads.

HIPOTRUK

HIPOTRUK specializes in high-quality spacers compatible with German brand modular trailers, offering cost-effective, durable solutions:

- Intermediate Spacers: Available in standard lengths like 3m, 6m, and 9m, HIPOTRUK’s intermediate spacers extend the loading platform efficiently. They’re engineered to fit with various hydraulic modular trailers, ensuring compatibility and reliability.

- Telescopic Spacers: HIPOTRUK’s telescopic spacers function as extendable frames, allowing trailers to increase length dynamically for longer loads while minimizing the need for additional axles. Custom sizes are offered, with hydraulic interconnect pipelines for seamless performance between modules. HIPOTRUK prioritizes quality in design to prevent issues like pin bending or equipment breakdown, enhancing safety and durability.

Applications of Spacers in Heavy Transport

- Wind Power Projects: Used for transporting wind turbine blades and tower sections.

- Construction Industry: Essential for transporting large materials like steel beams and bridge components.

- Industrial Equipment Transport: Ideal for carrying heavy machinery that requires extended trailer support.

Conclusion

In conclusion, spacers are indispensable for enhancing hydraulic modular trailer adaptability and efficiency, allowing operators to manage a wide range of oversized and heavy cargo safely. Spacers from reputable manufacturers like HIPOTRUK provide options that help ensure stability, cost-effectiveness, and versatility across industries.