The mining industry requires the movement of extremely heavy and oversized machinery, from excavators and dozers to massive drill rigs and dump trucks. Moreover, transporting this equipment safely and efficiently is a logistical challenge that hydraulic modular trailers (HMTs) are uniquely equipped to handle. With their high load capacity, modular flexibility, advanced maneuverability, and safety features, HMTs are a top choice for moving mining equipment across rough terrains and remote mining locations. Here’s why hydraulic modular trailers are indispensable for mining equipment transport.

Table of Contents

ToggleHigh Load Capacity for Massive Mining Machinery

Mining equipment can weigh hundreds of tons, and HMTs are designed to easily handle these substantial loads.

- Supporting Loads up to 5,000 Tons: Some HMT configurations can support loads up to 5,000 tons when multiple modules are combined, making them ideal for transporting oversized mining machinery.

- Examples of Heavy Mining Equipment:

- Excavators: Large excavators used in mining operations require robust trailers for safe transport.

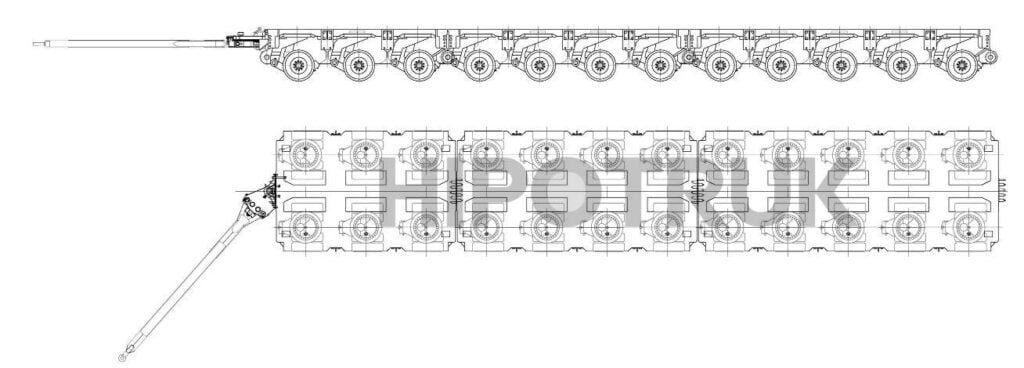

- Mining Shovels: For example, transporting a CAT 6030 Hydraulic Mining Shovel, which weighs around 330 tons, requires a 12-axle line modular trailer.

- Drill Rigs and Dump Trucks: Heavy drill rigs and dump trucks also need specialized trailers with high load capacities to ensure stability and safety.

This load-bearing capability makes HMTs ideal for carrying the largest pieces of mining equipment, reducing the need for multiple trips and enhancing operational efficiency.

Modular Design and Flexibility

The modular design of HMTs allows for various configurations, providing versatility for transporting equipment of different shapes and sizes.

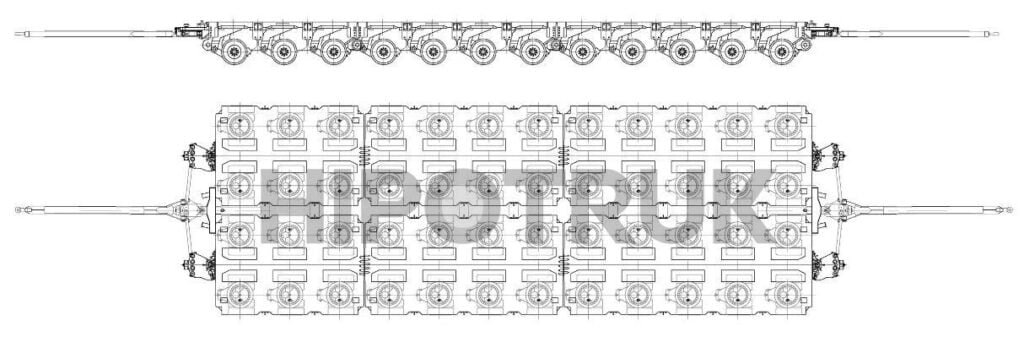

- End-to-End or Side-by-Side Configurations: HMTs can be connected end-to-end for long equipment or side-by-side for wider loads, adapting to different types of machinery that may not be easy to disassemble.

- Tailored for Different Equipment Sizes: Whether moving large mining shovels, drills, or dozers, the trailer setup can be customized to meet the specific dimensions and weight requirements of each load.

This flexibility is particularly beneficial in mining, where equipment can vary greatly in size and weight, ensuring that one transport solution can handle a wide range of machinery types.

Even Weight Distribution for Load Stability

Heavy mining equipment often has an uneven weight distribution. HMTs use hydraulic suspension to distribute weight evenly across all axles, reducing stress on both the trailer and the cargo.

- Hydraulic Suspension System: This system ensures stability by adjusting to the weight and dimensions of the load, preventing damage to the equipment and reducing wear on road infrastructure, especially in remote mining locations.

- Benefits of Even Weight Distribution:

- Minimizes strain on axles and trailer structure

- Reduces the risk of equipment damage during transit

- Helps prevent road damage, particularly useful in isolated, rugged mining areas

Maneuverability in Tough Mining Terrain

Mining sites are typically located in remote areas with rough, uneven terrain. HMTs provide the maneuverability required to navigate these challenging routes.

- Advanced Steering Angles: With steering angles of up to 55°, HMTs are highly maneuverable, making it easier to navigate narrow mine roads, tight corners, and steep inclines or declines.

- 360-Degree Movement and Sideways Motion: Some models like SPMT offer 360-degree steering, allowing for carousel turns and sideways movement. This feature provides precise control, especially useful in confined mining environments with limited space.

The advanced maneuverability of HMTs allows them to transport mining equipment safely, even in challenging terrains and through narrow routes within mine sites.

Height Adjustability for Clearances and Loading Ease

The hydraulic systems in HMTs allow operators to adjust the platform height, an essential feature when transporting tall or bulky mining equipment.

- Clearing Obstacles: Adjustable height makes it easier to navigate under bridges, through tunnels, or around other obstacles that might be encountered en route to mining sites.

- Efficient Loading and Unloading: Height adjustability also facilitates loading and unloading of heavy equipment without needing additional lifting equipment, saving time and enhancing operational efficiency.

This feature is particularly beneficial in mining, where large, tall machinery often needs to be moved through varying terrains and under infrastructure constraints.

Essential Safety Features for Mining Transport

Transporting heavy mining equipment comes with inherent safety risks, and HMTs are equipped with advanced features to mitigate these risks.

- Hydraulic Suspension for Stability: The suspension system ensures the load remains stable, adjusting automatically to uneven terrain and reducing the risk of tipping.

- Advanced Braking Systems: HMTs come with hydraulic braking systems that offer precise control, particularly useful when moving equipment on steep slopes.

- Load Securing Mechanisms: Hydraulic locking pins and load securing mechanisms keep heavy machinery stable during transit, preventing movement that could jeopardize safety.

These safety features provide a secure transport solution, protecting both operators and the high-value equipment being transported.

Cost Efficiency for Large-scale Mining Operations

While hydraulic modular trailers may require a higher initial investment than traditional transport solutions, they offer substantial cost benefits in the long run.

- Reduced Need for Multiple Trips: With their high load capacity, HMTs can transport multiple pieces of machinery in one trip, minimizing the cost and time associated with equipment relocation.

- Durability and Low Maintenance Costs: Built to endure the rigors of mining environments, HMTs experience less wear and tear, reducing the frequency and cost of repairs.

- Enhanced Productivity: By enabling the efficient movement of large machinery, HMTs reduce downtime in mining operations, allowing equipment to be moved quickly between sites to meet project needs.

The overall efficiency and durability of HMTs translate into long-term savings, making them a valuable investment for mining companies looking to optimize their logistics.

Versatility Across Different Types of Mining Equipment

Hydraulic modular trailers are designed to transport a wide range of mining equipment, making them invaluable for operations that require frequent equipment movement.

- Suitable for Various Machinery Types:

- Draglines: Large excavators used in surface mining

- Wheel Loaders: Used for loading materials onto trucks

- Dozers: Essential for clearing debris and preparing mine sites

This versatility ensures that HMTs can be used for various hauling tasks, reducing the need for specialized trailers and maximizing the return on investment.

Conclusion

Hydraulic modular trailers are essential for mining operations, providing a robust, adaptable, and safe solution for transporting heavy-duty equipment across challenging terrains and remote sites. With their high load capacity, advanced maneuverability, modular flexibility, and safety features, HMTs offer an efficient, cost-effective transport solution tailored to the unique demands of the mining industry.

For mining companies looking to enhance their logistics and reduce downtime, investing in or renting hydraulic modular trailers delivers significant advantages over traditional transport options. As mining projects become more complex, hydraulic modular trailers will continue to play a vital role in ensuring the safe, efficient, and reliable transport of large-scale mining equipment.