- Built to YOUR Success !

- info@hipotruk.com

- +86 13864095913

Let’s be honest—I’m not a hydraulic modular trailer expert by any means. But I have been spending a week diving into research and chatting with our engineers, I also have combined my decade of sales experience to put together this guide for you. I hope it helps!

In this comprehensive article, I will take you to explore everything you need to know about hydraulic modular trailers. We’ll cover:

Plus, I’ll share insights on some of the top hydraulic modular trailer manufacturers worldwide and tips on choosing the best hydraulic modular trailer supplier for your needs. Let’s get started!

A hydraulic modular trailer is a heavy-duty transporter, often called a modular trailer, hydraulic multi-axle trailer, or hydraulic platform trailer. What makes it special are its hydraulic steering system, hydraulic suspension, independently steerable axles, and the ability to connect multiple modules both side by side and end to end. The deck of the trailer can be lowered or raised by the hydraulic suspension for loading or removing loads.

A Hydraulic Modular Trailer (HMT) is one of the safest ways to transport abnormal and oversized loads that are too big or heavy to take apart. What’s more, goosenecks, drawbars, drop decks, spacers, turntables, vessel bridges, and other additional components ensure that the trailers are optimally adapted to any transport requirements.

These trailers’s chassis are built from high-tensile steel, like Chinese Q550 or Q690 high-tensile steel materials, which makes them incredibly strong. They can handle huge weights with the help of tractor trucks that push or pull the trailers using a drawbar or gooseneck, or with the hydraulic power pack to become self-propelled modular trailers (SPMT).

Hydraulic modular trailers work by using an advanced hydraulic suspension system, hydraulic steering, and a high-loading capacity platform to get the job done. They offer solutions for any heavy-duty transport needs. You can customize them with additional components like drop decks, spacers, vessel bridges, and turntables. Plus, you can combine multiple modules both lengthwise and sideways to fit different loads perfectly.

Hydraulic modular trailers are incredibly versatile heavy-duty transporters, providing a cost-effective and flexible solution for moving heavy-duty loads. It would be a waste to use them for light cargo, as they are primarily designed for oversized loads. Let’s look at how they’re used in different industries:

In power stations, We often use these trailers to transport heavy generators and transformers that weigh from 80 tons up to more than 200 tonnes. Their high loading capacity and stability make them perfect for handling these massive components.

In the chemical industry, We often use these modular trailers with drop decks or vessel bridges to transport large abnormal chemical tanks, such as large LNG tanks. Their robust construction frame ensures even the heaviest and most sensitive loads are moved without any risk.

Hydraulic modular trailers are employed in mining operations due to their excellent lateral stability.

All in All, These trailers are versatile and cater to a wide range of industries that require the transportation of heavy, oversized, and difficult-to-disassemble loads efficiently and safely

This section provides an overview of the main components of a hydraulic modular trailer. I will detail the features, and functions of each component.

The main beam of the frame is a box-shaped carrying structure. It is made of high-tensile strength steel, such as Q550 or Q690, with a yield strength of 550 MPa to 690 MPa, which ensures the frame’s stability and reliability under heavy loads.

The frame has a box-shaped center beam and strong crossbeams, which make it very rigid. This design allows the frame to handle extremely heavy point loads and concentrated load without any issues.

The steering system, air tank, and hydraulic oil tank are all built into the frame. This integration protects these parts from damage and corrosion, ensuring they last longer and require less maintenance.

The length of a hydraulic modular trailer varies depending on how many modules you choose. For example, the length of a 4-axles HIPOTRUK HPG1 module is 6000m. With a wheelbase of 1,550mm per axle, you can calculate the total length based on the number of axle lines.

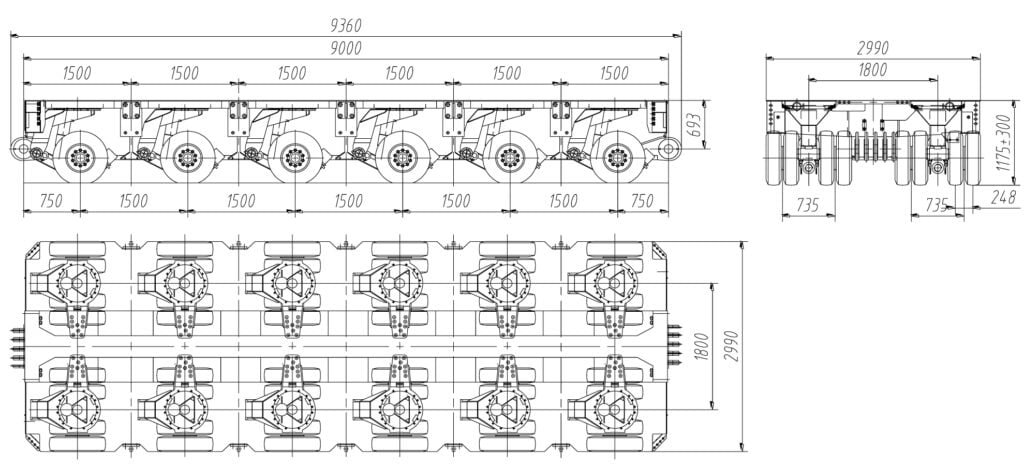

Typically, the platform width of a hydraulic modular trailer is 2,990mm. But, for special transport needs, the width can be increased through side-by-side combinations to reach 4,000mm or even 6,000mm.

Typically, The platform height generally ranges from 680mm to 1,175mm with a suspension stroke of ±300mm to accommodate uneven road surfaces.

For instance, China Hipotruk offers models with a minimum height of 680 mm for over-height cargo transportation, whereas other manufacturers might have a minimum height of 770 mm.

The load capacity of hydraulic modular trailers typically ranges from 22 tons to 45 tons per axle line. For example, the China Hipotruk G1 can handle up to 45 tons per axle line.

To determine the total weight capacity, multiply the load capacity by the number of axles. For example, a 10-axle trailer can carry between 220 and 450 tons( 22ton~45ton X 10 axle lines).

However, you can’t ignore one important thing,which is your local regulations. While the load capacity can reach up to 45 tons per axle, many countries restrict each axle to carry only 10-12 tons. Therefore, when purchasing a trailer, ensure it has enough axles to handle your transport needs and also comply with your country’s transportation regulations.

For the Hydraulic modular trailer axle, There are 2 axles, 3 axles, 4 axles, 5 axles, 6 axles, 8 axles, 10 axles, 12 axles, and more axles you can choose for your transportation needs. The more axles you choose, the higher the load capacity of the trailer.

The main components of the steering mechanism include the steering central panel, the steering orifice plate welded to the bogie frame, the steering cylinders, and the steering rods. These components work together to ensure smooth operation and reliable steering performance.

There are two types of wheel bogie steering systems used in hydraulic modular trailers: the ball bearing race ring and pivot bearing make the modular trailer.

It is designed for off-road operations, capable of handling heavy loads within a worksite, and engineered for safety and high performance in heavy-duty tasks.

For instance, the China Hipotruk G1 modular trailer and German modular trailers adopt a ball-bearing race ring steering system, which can achieve a 55-degree turning angle.

t is intended for on-road transport, with reinforced frames to manage axle loads, making it ideal for in-plant operations and providing stable and reliable transportation.

For instance, China Hipotruk N3 modular trailer and Nicolas modular trailer adopts pivot bearing steering steering system, which can achieve a 55-degree turning angle.

In other word, the trailer can be lowered to the ground to make it easier to load heavy items or go cross some places with limited height, and also raised to a suitable height for transport.

The hydraulic gooseneck is the pivotal component that connects the modules to the tractor truck. It can distribute weight evenly between the tractor and modules, ensuring optimal balance and stability. The gooseneck can also adjust its height, making it easier to load and unload cargo.

Besides, The hydraulic mechanism of the gooseneck can receive steering signals from the truck, which makes the trailer’s axles turn with the truck simultaneously.

The hydraulic power pack is like the engine for the trailer’s hydraulic system. It provides the necessary power to operate various hydraulic functions, such as the suspension system, gooseneck adjustments, and steering mechanisms. Typically, these power packs are equipped with high-performance hydraulic pumps, motors, and reservoirs to ensure reliable and efficient operation.

Hydraulic modular trailers are equipped with a compressed air brake system to ensure safety during transport. This system includes double brake chambers, relay valves, and ABS (Anti-lock Braking System), which prevent wheel lockup during sudden braking, maintaining control and stability. These features provide powerful and responsive braking, essential for controlling heavy loads.

The electrical system in hydraulic modular trailers is designed for reliability and efficiency, offering key features such as 12V or 24V voltage options to accommodate different country standards. It includes energy-efficient and long-lasting LED lighting for clear visibility, integrated control panels for easy monitoring and control of various trailer functions, and advanced wiring harnesses to ensure durability and protection against environmental factors, thereby reducing the risk of electrical failures.

Used for manual steering, lifting, and lowering operations. They provide the necessary interface for controlling the trailer’s hydraulic systems.

The technical specifications and dimensions of hydraulic modular trailers are not the same depending on the specific model and manufacturer. Here, I outline the common dimensions and specifications of a 6-axle modular trailer for your reference.

Hydraulic goosenecks connect the trailer to the towing vehicle, offering adjustable weight distribution for optimal balance and steering synchronization. They also have a lifting function for height adaptability and can partially bear the cargo weight, serving as a superior alternative to traditional drawbar equipment.

Goosenecks typically feature two pairs of steering cylinders to support both the front and rear steering systems of the trailers. The rear gooseneck clearance and coupling height are adjustable to fit most standard truck tractors.

Hydraulic modular trailers can be pulled and pushed by a drawbar. The drawbars are available in lengths from 2m to 5m, designed to meet specific towing needs.

The drawbar offers superior maneuverability in tough conditions and is the most straightforward way to operate a modular trailer. With a drawbar attached at both ends, the trailer can easily reverse its main driving direction when necessary.

For modular trailers with 18 axle lines or more, it is generally recommended to use a drawbar system instead of a gooseneck. To enhance payload capacity, reduce axle loads, or optimize the bending moment, drawbar trailers can be configured in 3-file (1+1/2) or 4-file (1+1) side-by-side arrangements.

Hydraulic modular trailers can be pulled and pushed by a drawbar. The drawbars are available in lengths from 2m to 5m, designed to meet specific towing needs.

The drawbar offers superior maneuverability in tough conditions and is the most straightforward way to operate a modular trailer. With a drawbar attached at both ends, the trailer can easily reverse its main driving direction when necessary.

For modular trailers with 18 axle lines or more, it is generally recommended to use a drawbar system instead of a gooseneck. To enhance payload capacity, reduce axle loads, or optimize the bending moment, drawbar trailers can be configured in 3-file (1+1/2) or 4-file (1+1) side-by-side arrangements.

If the length of the equipment you are going to transport is over 9 meters, you have to choose a split-type dropdeck. This is because there are no steel plates over 9 meters long, so you have to combine two, three or more dropdecks by pin joint for transporting longer cargo. However, this situation is rarely encountered. Of course, the benefit of using a split-type dropdeck is that you can freely combine the appropriate dropdecks to transport different lengths of cargo, achieving the purpose of having one dropdeck serve multiple uses.

If the length of the equipment you are going to transport is over 9 meters, you have to choose a split-type dropdeck. This is because there are no steel plates over 9 meters long, so you have to combine two, three or more dropdecks by pin joint for transporting longer cargo. However, this situation is rarely encountered. Of course, the benefit of using a split-type dropdeck is that you can freely combine the appropriate dropdecks to transport different lengths of cargo, achieving the purpose of having one dropdeck serve multiple uses.

The vessel deck, also known as a vessel bridge, is available in various designs and payload capacities. It is ideal for transporting higher and wider abnormal tanks, vessels, long oversized containers, and other equipment.

The vessel deck normally adopts a splicing method to increase its length to transport long cargo, and its width can be extendable by a hydraulic system.

HIPOTRUK’s Vessel Decks are designed with versatile parameters to accommodate a variety of transport needs. HIpotruk offers deck heights of 450 mm, 500 mm, and 650 mm. The width ranges from 3,000 mm to 6,000 mm through hydraulic adjustable, and the length can be customized from 6,000 mm to 30,000 mm. This flexibility ensures that the vessel deck can handle a wide range of oversized and heavy cargo efficiently. What’s more, Hipotruk vessel decks can combined with all other brands, like Germam modular trailers and Nicolas trailers.

The Excavator deck is a specialized platforms designed for carrying large construction machines like excavators. They provide a stable and secure base for transporting heavy machinery

It is known as connection platforms, these spacers can be combined with existing modules to extend the overall length, particularly suitable for transporting long yet relatively light loads.

HIPOTRUK’s Intermediate Spacer is designed to extend the loading area or axle spacing without adding extra axle load. This makes it easier to distribute loads and transport various types of cargo efficiently. Available in lengths from 3,000 mm to 9,000 mm, these spacers are compatible with various brands, including German hydraulic modular series, Nicolas, Scheuerle, and Faymonville modular trailers.

It is also known as a telescopic beam, designed to increase the length of the trailer, allowing it to carry longer loads, such as long tanks or windmill turbine blades. You can talk with your supplier to provide you tailor-made extendable spacer that meets exactly your transport needs.

China HIPOTRUK’s Extendable Spacers are perfect for safely transporting extremely long loads. They start at a base length of 8,000 mm to 17,000 mm and can extend up to 45,000 mm. These spacers can extend 1 to 4 times, providing the flexibility needed to transport oversized cargo securely and efficiently.

Turntables are available for the transport of long and heavy loads. The front turntable is a pure mechanical system. Depending on the requirements, one can choose on the front bolster either a 1-point or a 2-point bearing using removable sliding shoes.

The rear turntable is generally equipped with a hydraulic self-tracking device to steer the rear dolly automatically.

In addition to the standard 2-file turntable, tailor-made turntables for 3-file and/or 4-file trailers with load repartition frames are available upon request.

The Blade Lifter, also known as a wind blade adapter, is cleverly designed for transporting wind turbine blades, especially through challenging mountainous regions. When integrated with a hydraulic modular trailer or SPMT, SPT module, this system uses advanced hydraulic cylinder control and a slew bearing to tilt the blade up to 60 degrees. This feature is crucial for safely navigating around obstacles like trees, cliffs, buildings, and power lines, ensuring secure and efficient transport of these massive blades.

The Wind Tower Adapter is specifically crafted for moving windmill tower segments and is essential in wind turbine logistics. When combined with hydraulic multi-axle modular trailers, it can handle tower segments weighing up to 150 tons and with diameters up to 6500mm.

The Girder Frame is central to the girder bridge trailer, strategically placed on both the front and rear transport modules to support heavy loads. The frame “hoists” the load and distributes it evenly to the multi-axle transport modules at both ends, ensuring balanced load sharing. Without wheel restrictions beneath the frame, the overall transportation height can be significantly lowered, even to ground level, which is beneficial for height-sensitive transports. The girder bridge trailer provides ease and safety in loading and unloading and, in some models, does not require additional lifting equipment. Additionally, the flexible steering structure of the split-type transporter allows for easy navigation, even in tight corners and with long vehicle lengths.

Hydraulic modular trailers can be configured in various ways to meet specific transportation needs. The combination forms include drawbar combinations, gooseneck combinations, self-towing configurations, drop decks, vessel bridges, intermediate and extendable spacers, excavator decks, and turntables. These conbination provide flexibility in transportation, including options such as a semi-trailer, a standard trailer, a self-propelled trailer and different types of accessories. Here’s how each setup works:

This modular approach offers a range of configurations across different series, including the 2-file, 3-file, and 4-file side-by-side combinations or end-to-end combinations with a drawbar. The primary distinction among these setups lies in the specific accessories utilized.

This setup includes a drawbar, power pack, modular unit, side steering frame, and additional combination accessories. It is suitable for transporting various types of cargo, with options extending up to 32 axle lines. Additional equipment like flat beams or low flat beams can be added for enhanced versatility.

This configuration features a drawbar, power pack, side steering frame, modular unit, combination accessories, half modular unit, and one or two central steering frames. It offers upgraded capabilities compared to the 2-file setup, providing more functionality and adaptability.

This setup includes more complex arrangements with additional modular units and central steering frames, allowing for the transportation of even larger and heavier loads

This specific configuration includes the STZ-V gooseneck, a full or half modular unit, a power pack, and various accessories to form a versatile hauling solution. Capable of supporting up to 16 axle lines, it allows for the selection of a modular unit that fits the cargo’s specific needs. Although this setup performs well in many transport situations, it is not ideal for transporting over-length goods. However, adding auxiliary equipment like a flat beam can improve its functionality, making it a versatile choice for a wide range of transportation requirements.

The turntable setup introduces a highly flexible combination for modular transport, featuring a drawbar, a turntable mechanism, a modular unit, a power pack, a side steering frame, and assorted combination accessories.

The key element, the turntable, stands out for its ability to be used in tandem, especially when transporting extra-long items. This innovative approach ensures smooth and efficient handling of oversized loads by providing additional rotational maneuverability.

By integrating the PPU device with module units and self-propelled modules, the trailer becomes autonomous. This setup includes a power unit that supports hydraulic movement, an air brake system, a lifting mechanism, and steering capabilities.

These innovative configurations allow the modular trailer to replace traditional vehicles for specific tasks, particularly in transporting heavy loads at speeds under 5km/h. Each combination offers unique advantages tailored to different hauling requirements, showcasing the modular trailer’s adaptability and efficiency in heavy transportation.

The drop deck is low to the ground, making it ideal for carrying tall items like transformers under bridges or power lines. It is firmly attached to the trailer and can quickly connect to other parts.

This setup is great for moving large, tall tanks, subway train units, or equipment. The vessel bridge can adjust its size to fit different loads, providing flexibility in handling oversized cargo

Intermediate spacers lengthen the trailer, making it useful for carrying long but not too heavy items. These spacers provide additional length without significantly increasing the load capacity

Also known as telescopic beams, these spacers extend the trailer’s length for carrying longer items. They are adjustable, allowing the trailer to adapt to various cargo lengths

This is a special platform on the trailer designed for carrying large construction machines like excavators. It provides a stable and secure base for transporting heavy machinery.

It is used for very long and heavy loads, the turntable combination includes a mechanical front part and a self-moving rear part to help steer the trailer. This setup enhances maneuverability and stability for transporting exceptionally large items.

There are various types of hydraulic modular trailers for meeting specific transportation needs, I can outline main types for your reference.

These heavy-duty trailers are designed for extremely heavy and oversized loads. They have a high load-bearing capacity and are known for their sturdiness and durability. Common brands include China HIPOTRUK G1 modular trailer, German hydraulic modular trailer, etc. The two brand’s modular trailers have a load capacity of 45 tonnes per axle.

These trailers are a light version, also designed for heavy loads but with a reduced weight for easier handling and transport. The common brands like China HIPOTRUK N3 modular trailer and German hydraulic modular model trailer.

SPMTs are like hydraulic modular trailers but with their own built-in power units (PPUs) for self-propulsion. They are ideal for situations where space is too tight for external tractors, such as some clinets use the SPMT in inside of their shipyard or factory. SPMTs are incredibly versatile and can move extremely heavy loads without needing additional towing vehicles.

SPMTs is used for extremely heavy or awkward loads within confined spaces like factories or shipyards, for tasks such as relocating large machines, assembling large ship sections, or positioning heavy equipment in industrial plants.

Hydraulic modular trailers are essential for transporting large and heavy cargo, commonly seen at construction sites and shipyards. These powerful vehicles are controlled via computer or control panel, enabling them to handle enormous weights. When selecting a modular trailer, factors such as versatility, durability, and capacity are key. This article introduces some of the leading hydraulic modular trailer manufacturers worldwide.

As China’s foremost producer of Hydraulic Modular Trailers, HIPOTRUK excels in customizing and manufacturing trailers for a payload range from 25 ton to over 15,000 ton. Our design capabilities enable us to tailor hydraulic modular trailers with diverse specifications and ensure compatibility with your current models from German, Nicolas, and other prestigious European manufacturers.

HIPO’s reach is global, with a significant presence in Europe, America, South America, Asia, and Africa. Their customer-focused approach ensures clients receive optimal solutions and support throughout the trailer’s lifecycle.

Goldhofer, with roots dating back to 1705, is a globally recognized leader in transport solutions. Their trailers are designed for heavy-duty on-road and off-road haulage, airport operations, and oversized cargo transport. Operating from a 100,000 sq. meter facility, Goldhofer produces high-quality heavy-duty modules, trailers, and semi-trailers, catering to diverse transportation needs, including airport cargo movement.

Kamag, part of the TII Group, is based in Ulm and boasts a rich history in heavy-duty vehicle manufacturing. With over 300 employees and a 45,000 sq. meter premises, Kamag specializes in modular transporters, terminal logistics vehicles, and industrial vehicles. Their offerings include special transporters, power boosters, and shipyard transporters, renowned for their reliability, efficiency, and customer service. Kamag also provides solutions for the aerospace and metal industries.

Cometto is famous for its electronic modular self-propelled vehicles, heavy-duty trailers, and special self-propelled trailers. Serving industries such as steel, construction, aerospace, wind energy, and shipbuilding, Cometto offers modular transporters with various power pack units, including diesel and hybrid options, tailored to customer needs.

Scheuerle, the largest production site in the TII Group, excels in building heavy-duty vehicles for road transport. Known for pendulum axles controlled via hydraulics, Scheuerle operates a 70,000 sq. meter facility producing vehicles for road transportation, compact automobiles, power boosters, self-propelled modular trailers, and more. With a rich history and cutting-edge technology, Scheuerle stands as an industry leader.

Nicolas, another TII Group member, specializes in heavy-duty vehicles, including self-propelled modular trailers. They offer compact and modular vehicles for special and road transport, serving industries like mining, wind energy, and aerospace. With a history dating back to 1855, Nicolas is known for developing reliable modular trailers.

Selecting a reputable and reliable modular trailer manufacturer is crucial for handling heavy and oversized loads. The manufacturers highlighted – HIPOTRUK, Goldhofer, Kamag, Cometto, Scheuerle, Nicolas, and Faymonville – are leaders in the industry, offering unique products and solutions. By considering quality, durability, and customer reviews, you can choose the best hydraulic modular trailer manufacturer to meet your needs.

If you have years of experience using hydraulic modular trailers, you probably know what to look for when purchasing a new one. However, here are some key factors to consider to ensure you get the best trailer for your needs.

By choosing the right combination of modular trailer accessories, you can transform your trailer into a versatile and powerful tool capable of handling a wide range of cargo types.

Whenever possible, take the time to visit potential manufacturers to ensure you are making an informed decision. Here are some key benefits and steps to consider:

In summary, visiting potential manufacturers can give you a clearer picture of their capabilities, help you negotiate better deals, and build stronger partnerships. It’s a step that can make a significant difference in ensuring you choose the right supplier

When it comes to quality and performance testing, many suppliers claim their hydraulic modular trailers are rigorously tested before delivery. However, not all of them have the necessary testing equipment or procedures in place. Here’s what you should look for to ensure your supplier meets high standards:

At our factory, we ensure that every Hipo modular trailer undergoes comprehensive testing before shipping. This includes a rigorous seven-day driving test to assess overall quality and performance. Key checks during this process include:

Steering Axle Functionality: We ensure there are no errors in the steering axle, which is crucial for the trailer’s maneuverability and safety.

Operational Sounds: We listen for any unusual sounds during the operation that could indicate underlying issues.

Oil Leak Inspection: We check for any signs of oil leaks, which can affect the trailer’s performance and longevity.

It’s important to verify that your supplier’s quality control measures meet or exceed national standards. For instance, our testing procedures comply with China’s stringent quality and safety standards, ensuring that every trailer we deliver is reliable and safe.

Balancing quality and price is crucial when purchasing hydraulic modular trailers. Extremely low prices often indicate lower quality, especially in the Chinese market where appearance alone can be deceptive.

If a supplier offers prices that are 20% lower than the market average, proceed with caution. Such low prices can signal poor quality or even scams. It’s advisable to visit the factory to inspect the products personally before making a purchase. Remember, the cheapest option often leads to higher costs in the long run due to frequent repairs, maintenance, or the need for replacement.

It’s wise to adjust your budget to prioritize product quality. Investing a bit more upfront can save you from continuous problems and expenses later. As the saying goes, you usually get what you pay for. Ensuring higher quality from the start can lead to greater satisfaction and fewer issues down the line.

Working with a reputable supplier is essential. They can help you understand the differences between modular trailer types, explain their features, and recommend the best model for your needs. A trusted supplier ensures you get a quality product that meets your specific requirements.

Consider the warranty and customer support offered by the manufacturer. Choose a trailer from a reputable manufacturer that provides a comprehensive warranty and reliable customer support. This ensures you have assistance if any issues arise and that your investment is protected.

Investing in the best hydraulic modular trailer for your job is crucial, as the right trailer will serve you reliably for years. Choosing a Chinese hydraulic modular trailer can be a cost-effective option, as the price is typically about one-third of European products, making it an attractive choice for combining with your existing equipment.

We warmly invite you to visit HIPOTRUK and see our manufacturing capabilities firsthand. You’ll witness our advanced production lines, quality inspection equipment, and meet our professional service team. This visit will allow you to discuss your requirements directly with our technical engineers, leading to quicker solutions, better pricing, and improved delivery times. We understand that visiting us is a significant journey, which demonstrates your serious intent to make a valuable purchase.

Contact us 24×7 to answer your questions and requirements.

Contact us 24×7 to answer your questions and requirements.

+86 13864095913

+86 13864095913

We will contact you within 10mins, please pay attention to the email with the suffix “@hipotruk.com”.

We will contact you within 10 minutes and provide you with the Best Factory Price to Save Your Purchase Cost!