In heavy haulage, transporting oversized and irregularly shaped loads requires careful planning and specialized equipment to ensure stability and safety. Vessel bridges are essential components in hydraulic modular trailers, providing additional stability for exceptionally large or complex cargo. By integrating with the trailer’s hydraulic systems and offering customizable configurations, vessel bridges significantly improve load stability and transport efficiency.

Table of Contents

ToggleWhat Are Vessel Bridges in Heavy Haulage?

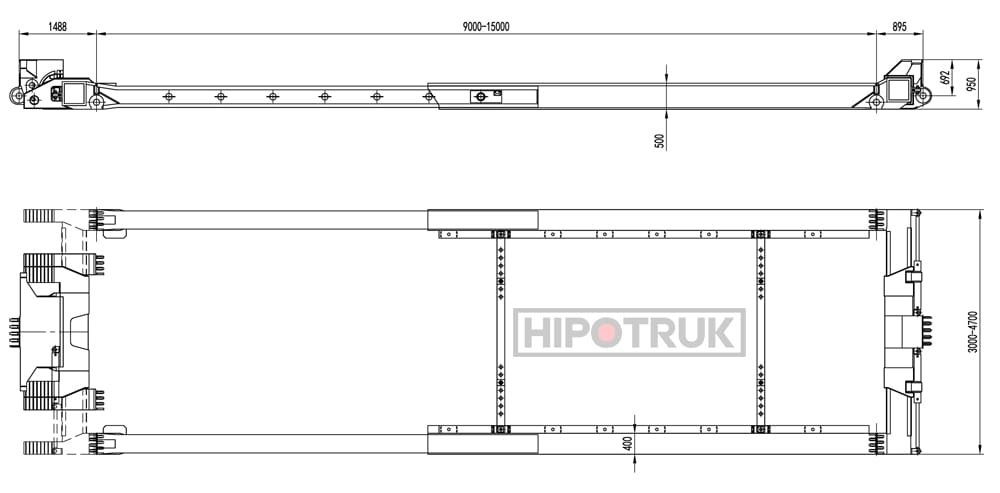

A vessel bridge is a structural attachment used with hydraulic modular trailers to create a stable platform that supports and distributes the weight of oversized cargo evenly. These bridges can adapt in size and shape to match the specific requirements of different loads, making them ideal for transporting high-center-of-gravity items and heavy machinery.

Key Functions of Vessel Bridges

- Customizable Dimensions: Adjustable in length and width to fit various cargo sizes, ensuring balanced support.

- Low Center of Gravity: Positions loads closer to the ground, enhancing stability during transport.

- Curvature Adjustment: Advanced models can adjust curvature for transporting irregularly shaped cargo.

How Vessel Bridges Improve Load Stability

Vessel bridges improve load stability through even weight distribution, a lower center of gravity, and flexible configurations, all of which contribute to a safer and more stable transport experience.

1. Customizable Dimensions for Optimal Load Support

The dimensions of vessel bridges can be adjusted to accommodate various cargo sizes, ensuring that the load is supported along its entire length.

- Adjustable Length and Width: Operators can modify the dimensions to provide optimal weight distribution across the trailer.

- Enhanced Cargo Stability: With the ability to customize based on load size, vessel bridges ensure that even irregularly shaped cargo is securely supported.

2. Lower Center of Gravity for Greater Stability

Vessel bridges allow cargo to be positioned closer to the ground, effectively lowering the load’s center of gravity. This positioning reduces the risk of tipping, even for high-center-of-gravity cargo.

- Improved Load Balance: Lowering the center of gravity increases the stability of the load during transport.

- Reduced Tipping Risk: Ideal for taller items like tanks or industrial equipment that would otherwise be prone to tipping.

3. Even Weight Distribution Across Multiple Axles

By evenly distributing weight across multiple axles, vessel bridges prevent overloading at specific points, which helps maintain balance and stability throughout the journey.

- Balanced Load Support: Reduces stress on individual axle lines, minimizing the risk of structural strain.

- Increased Safety: Prevents uneven load distribution, which could cause instability, especially during turns or on uneven roads.

4. Curvature Adjustment for Irregular Cargo

Some advanced vessel bridges have a curvature adjustment feature that allows them to accommodate irregularly shaped or curved cargo. This ensures that the load is consistently supported along its length.

- Custom Support for Curved Items: Allows for transportation of unique items like wind turbine blades or other curved structures.

- Prevents Load Shifting: Ensures even support across the entire length, reducing movement during transit.

5. Integration with Hydraulic Systems for Real-Time Adjustments

Vessel bridges work in conjunction with the hydraulic systems of modular trailers, allowing for real-time adjustments to maintain load stability. This integration is essential for navigating uneven terrain or sharp turns.

- Hydraulic Suspension Control: Maintains consistent weight distribution across axles, adapting to changes in road conditions.

- Pneumatic Locking Mechanisms: Secure the vessel bridge, providing additional safety during transport.

Key Benefits of Vessel Bridges for Heavy Haulage

Vessel bridges offer several benefits that contribute to safer and more efficient heavy haulage, especially when transporting oversized or heavy cargo.

1. Enhanced Safety and Reduced Risk

By providing stable support and reducing the risk of tipping, vessel bridges improve the overall safety of heavy transport operations.

- Lower Center of Gravity: Reduces tipping risks, especially for tall or top-heavy loads.

- Secure Fastening: Integrated lashing points and pneumatic locks keep cargo stable, even on challenging terrain.

2. Improved Efficiency and Time Savings

With quick adjustments and reliable stability, vessel bridges save time during loading and unloading, reducing downtime and increasing operational efficiency.

- Efficient Loading and Unloading: Adjustable configurations make it easier to secure cargo quickly.

- Reduced Delays: Height and width adjustments allow for efficient navigation through tight spaces and under low-clearance areas.

3. Cost-Effective Solution for Diverse Loads

Vessel bridges offer a flexible, cost-effective solution for transporting various cargo sizes, eliminating the need for multiple trailer types.

- Multi-Use Adaptability: One vessel bridge can accommodate a wide range of cargo, reducing the need for custom trailers.

- Compact Storage: When not in use, retracted vessel bridges take up less storage space.

Applications of Vessel Bridges in Heavy Haulage

Vessel bridges are widely used across industries where transporting oversized and irregular cargo is essential. Their versatility makes them suitable for various heavy-haul applications.

- Construction and Infrastructure

- Bridge Sections: Efficiently transport large bridge segments to construction sites.

- Steel Beams: Move long steel beams and structural components required for infrastructure projects.

- Energy and Industrial Equipment

- Wind Turbine Components: Transport long blades and towers with curvature adjustments for stable hauling.

- Industrial Machinery: Ideal for heavy transformers, power generators, and refinery equipment.

- Transporting Heavy and Irregular Loads

- Vessel bridges provide the stability needed for unusually shaped cargo, preventing shifts during transport.

- Oversized Tanks: Move large tanks and vessels which require stable support.

- Heavy Industrial Parts: Transport bulky machinery used in mining and manufacturing sectors.

Advanced Features in Vessel Bridges for Load Stability

Certain vessel bridges offer advanced features that enhance their functionality and adaptability, allowing operators to handle complex transport requirements.

1. Hydraulic Support Legs

Hydraulic support legs allow for quick adjustments, accommodating changes in road conditions and preventing shifts during transit.

- Real-Time Adaptability: Hydraulic support legs maintain load stability on uneven terrain.

- Increased Safety: Prevents cargo movement, even on challenging surfaces.

2. Weight Distribution and Load Capacity Enhancement

Some vessel bridge designs incorporate weight-sharing beams that significantly increase load capacity, with some models capable of handling loads up to 350 tons.

- Increased Load Capacity: Provides higher capacity for extremely heavy cargo.

- Improved Balance: Weight-sharing beams distribute weight evenly, reducing strain on axles.

Choosing the Right Vessel Bridge for Your Haulage Needs

Selecting the right vessel bridge involves assessing load dimensions, weight requirements, and compatibility with existing trailer systems.

1. Evaluate Load Dimensions and Weight

Choose a vessel bridge that meets your typical loads’ length, width, and weight requirements, ensuring it can handle maximum cargo dimensions.

- Size and Weight: Ensure that the vessel bridge can accommodate your heaviest loads.

- Curvature Adjustments: Look for models with adjustable curvature for transporting curved items.

2. Confirm Compatibility with Modular Trailer Systems

Make sure the vessel bridge integrates seamlessly with your hydraulic modular trailer system, such as HIPOTRUK models.

- Trailer System Compatibility: Ensure alignment with existing modular trailer models and accessories.

- Hydraulic Integration: Verify that hydraulic connections are compatible with your current setup.

3. Consider Advanced Safety Features

For additional stability, consider vessel bridges with hydraulic support legs, pneumatic locking pins, and integrated lashing points.

- Secure Locking Mechanisms: Look for pneumatic locking pins for reliable positioning.

- Safety Lashing Points: Ensure secure fastening to prevent load shifts.

Summary: The Role of Vessel Bridges in Enhancing Load Stability

Vessel bridges are integral components in hydraulic modular trailers, significantly enhancing load stability, safety, and efficiency in heavy haulage operations. By enabling even weight distribution, lowering the center of gravity, and adapting to irregular cargo shapes, vessel bridges provide essential support for transporting oversized loads safely and efficiently.

Key Takeaways

- Customizable Stability: Vessel bridges can be adjusted to match the dimensions of various loads, improving stability.

- Enhanced Load Control: Provides a stable base, reduces tipping risks, and distributes weight evenly across the trailer.

- Versatile Applications: Used across multiple industries for transporting large construction, energy, and industrial equipment.

Incorporating vessel bridges into heavy haulage setups enables companies to handle complex transportation needs, ensuring that even the most challenging loads are moved safely and efficiently. This technology continues to play a vital role in the success of heavy transport projects worldwide.