Hydraulic modular trailers (HMTs) are versatile and adaptable transport solutions for moving heavy, oversized loads in industries such as wind energy, mining, and industrial manufacturing. Moreover, their high customization capacity allows them to meet specific load size, weight distribution, and route complexity requirements, making them indispensable for specialized transport tasks. This guide explores the customizable features of hydraulic modular trailers and how they benefit various applications.

Table of Contents

ToggleModular Design for Flexible Configurations

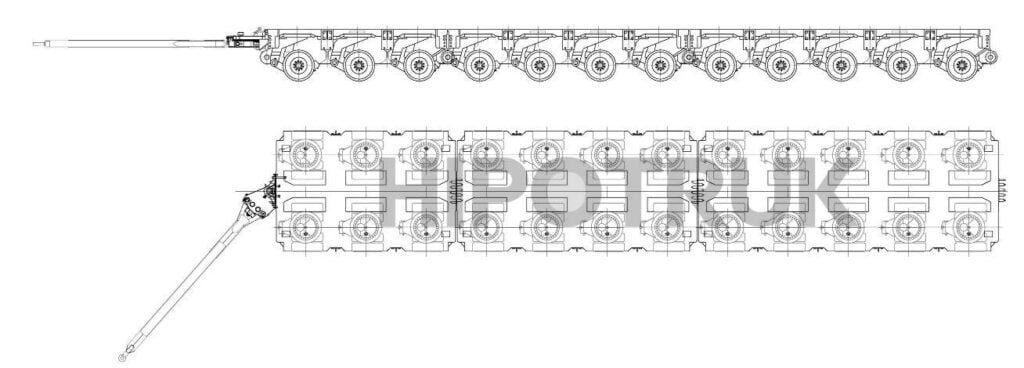

The modular design of HMTs enables trailers to be configured in multiple ways, accommodating a wide range of cargo dimensions.

- End-to-End and Side-by-Side Coupling: Trailers can be connected lengthwise or side-by-side, allowing for customized configurations supporting extremely large or long cargo, such as wind turbine blades or industrial machinery.

- Mechanical and Hydraulic Couplings: These coupling systems enable easy reconfiguration to match specific transport needs, making it possible to quickly adjust the trailer’s setup based on load requirements without extensive modification.

This modularity provides flexibility for transporting diverse loads and simplifies reconfiguration, maximizing the utility of each trailer.

Adjustable Platform Dimensions for Load Compatibility

Adjustable platform dimensions are essential for accommodating different types of cargo and navigating varied terrains.

- Width and Length Adjustments: Trailers can be extended in width and length using extendable spacers or telescopic beams to match specific cargo dimensions, such as the long blades of wind turbines or bulky mining machinery.

- Height Adjustability: The hydraulic system adjusts the platform height, crucial for transporting tall loads under bridges or through tunnels. Height adjustability also aids in loading and unloading operations.

These customizable dimensions enhance the trailer’s versatility, making it suitable for handling oversized equipment and adapting to challenging road conditions.

Advanced Steering Systems for Maneuverability

Steering systems on HMTs are designed to provide precise control, even in tight or confined spaces.

- All-Wheel Steering: All-wheel steering with angles of 45° to 55° allows for sharp turns and precise navigation, enabling the trailer to maneuver through narrow spaces or complex routes.

Advanced steering options are essential for trailers transporting oversized cargo through tight spaces or challenging environments, enhancing both control and safety.

Load Capacity Customization for Heavy-Duty Haulage

Customizing the load capacity of an HMT is vital for transporting extremely heavy equipment, from mining excavators to large construction components.

- Axle Configurations: The number of axle lines can be tailored to support varying load capacities, with some configurations supporting up to 5,000 tons. Adding more axles improves load distribution and enables the trailer to carry heavier loads safely.

- Hydraulic Suspension Systems: Hydraulic suspension ensures even weight distribution across all axles, adapting to uneven terrain and maintaining load stability during transit. This system reduces stress on both the cargo and the trailer, particularly on rugged routes.

These options allow HMTs to handle the heaviest loads safely, meeting the demands of industries like mining and construction where large, heavy equipment is common.

Specialized Accessories for Industry-Specific Needs

Specialized accessories enable HMTs to transport a wide range of cargo types, each requiring unique handling.

- Wind Blade and Tower Adapters: These adapters are specifically designed for wind turbine transport, securing blades and tower sections during transit. They ensure stability and protection for these delicate components.

- Vessel Bridges and Drop Decks: Ideal for transporting large tanks or equipment with a low center of gravity, these deck options support oversized cargo that requires additional stability.

- Excavator Decks: These specialized platforms carry heavy construction machinery like excavators, providing enhanced support and balance.

Industry-specific accessories increase the versatility of HMTs, allowing them to adapt to the unique requirements of different transport projects.

Power Pack Units (PPU) and Self-Propelled Capabilities

PPUs enable trailers to operate independently, offering enhanced maneuverability and control in confined spaces.

- Self-Propelled Options: Integrating PPUs for self-propelled capabilities allows trailers to move without a towing vehicle. This feature is useful for navigating complex work sites or when precise positioning is necessary.

- Diesel or Electric Power Options: Depending on operational and environmental needs, PPUs can be equipped with diesel or electric engines, providing flexibility for companies with specific power requirements or sustainability goals.

PPUs expand the functionality of HMTs, making them suitable for various operational contexts, including environmentally sensitive sites where electric power may be preferred.

Enhanced Safety Features for Secure Transport

Safety is paramount when transporting heavy and valuable cargo. HMTs offer a range of customizable safety features to minimize risks.

- Dual-Circuit Hydraulic Systems: These systems maintain hydraulic pressure across all components, ensuring stability and safety even in challenging conditions.

- Advanced Braking Systems: Equipped with WABCO and ABS and other braking enhancements, these systems provide control during transport, reducing the risk of accidents.

- Load Securing Mechanisms: Hydraulic locking pins and safety features like electronic stability control ensure that loads remain stable throughout transit.

These safety customizations are essential for controlling heavy cargo, particularly on long or difficult routes.

Operational Efficiency Enhancements for Cost Savings

Operational efficiency is crucial for reducing transport costs and minimizing downtime. HMTs offer several features that enhance efficiency.

- Quick Coupling Devices: Quick coupling devices facilitate fast assembly and disassembly of trailer modules, allowing operators to switch configurations with minimal downtime.

- Hydraulic Lifting Systems: Hydraulic lifting systems enable the trailer deck to be raised or lowered, simplifying the loading and unloading process without additional lifting equipment.

These efficiency-focused features reduce setup time and streamline transport operations, leading to cost savings and improved productivity for companies.

Conclusion

Customizable hydraulic modular trailers are essential tools for industries requiring specialized transport solutions. With modular design options, adjustable dimensions, advanced safety features, and specialized accessories, HMTs can be tailored to meet the specific needs of various heavy haulage applications. By investing in the right customizations, companies can ensure safe, efficient, and adaptable transport for a wide range of oversized and heavy cargo.

For businesses in sectors such as wind energy, mining, and industrial manufacturing, customized HMTs provide a versatile, reliable, and cost-effective solution that enhances operational efficiency and safety across diverse projects.