Extendable Vessel Bridges are critical components in hydraulic modular trailers, designed to transport exceptionally large, heavy, or irregularly shaped loads. These advanced accessories enhance the versatility and capacity of modular trailers, making them ideal for industries like construction, manufacturing, and heavy logistics. This article covers the purpose, design, key features, and benefits of extendable vessel bridges, providing insights into how they adapt hydraulic modular trailers for specialized transport needs.

Table of Contents

ToggleWhat is an Extendable Vessel Bridge?

An Extendable Vessel Bridge is an adjustable structure that attaches to hydraulic modular trailers to expand their load-bearing platform. This bridge is particularly valuable for transporting oversized items such as industrial vessels, bridge sections, and other large components.

Purpose and Functionality

- Length and Width Extension: Extendable vessel bridges increase both the length and width of trailers, accommodating a wide range of oversized cargo.

- Load Stability: By providing a stable base, these bridges ensure safe transportation of high-center-of-gravity loads and heavy equipment.

- Adaptability: With adjustable length, width, and other customizable options, extendable vessel bridges adapt to specific cargo needs, optimizing each transport task.

Key Features of Extendable Vessel Bridges

The extendable vessel bridge’s advanced features enable it to meet complex transport requirements efficiently and safely.

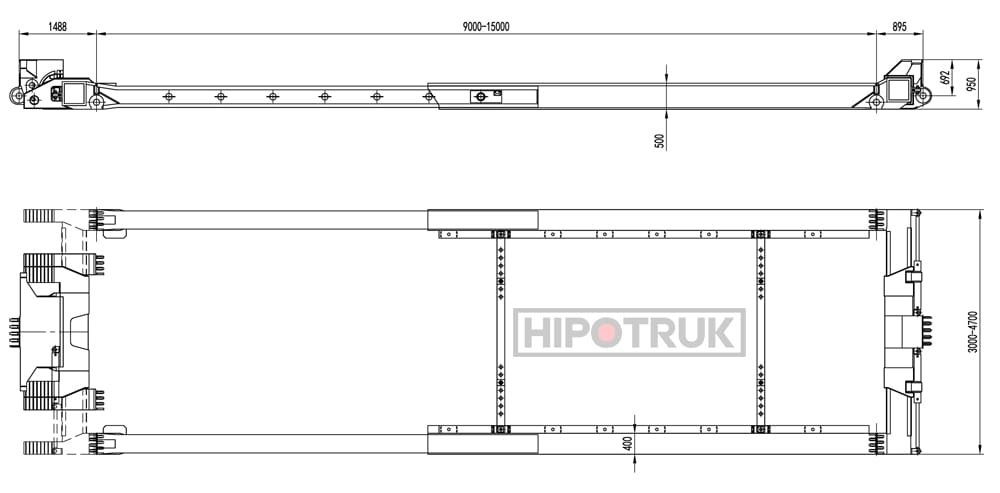

1. Adjustable Length and Width

Extendable vessel bridges can adjust in both length and width, allowing operators to tailor the trailer configuration to different cargo dimensions.

- Length Range: Most bridges extend from a compact closed length, such as 12 meters, to an extended length of up to 30 meters or more.

- Width Options: Width can be adjusted between 3,000 mm and 6,000 mm, allowing for flexibility in handling wide loads.

2. Advanced Design Features

Extendable vessel bridges incorporate additional design elements to improve both functionality and aesthetics.

- Internal Hinge Design: Reduces the need for external hydraulic hoses, creating a sleek, efficient design.

- Curvature Adjustment: Some models allow for curvature adjustments to transport curved or irregular cargo, ideal for items like wind turbine blades or large tanks.

4. Customizable Load Capacity and Structure

Manufacturers like HIPOTRUK offer customization options based on specific cargo needs.

- Construction Height Options: Common height choices include 450 mm, 500 mm, and 650 mm, adaptable to cargo height requirements.

- Weight Distribution Beams: Optional weight-sharing beams can increase load capacity up to 350 tons, supporting particularly heavy loads.

Benefits of Using Extendable Vessel Bridges in Hydraulic Modular Trailers

Extendable vessel bridges provide various benefits, making them essential for the efficient transport of oversized and heavy loads.

1. Enhanced Transportation Capacity and Versatility

The adjustable nature of extendable vessel bridges significantly increases a trailer’s transport capabilities.

- Accommodates Diverse Load Sizes: Extendable bridges can be customized to transport a wide range of cargo dimensions, from long beams to large vessels.

- Versatile Configurations: Ideal for handling various oversized cargoes across industries, adapting to different project requirements.

2. Improved Efficiency and Time Savings

With quick extension and secure locking mechanisms, extendable vessel bridges streamline the loading and unloading process, saving valuable operational time.

- Quick Extension Operations: Easy adjustments reduce preparation time, increasing the efficiency of transport tasks.

- Simplified Adjustments: Features like pneumatic locking pins allow for seamless length modifications during loading.

3. Enhanced Safety and Stability

Safety is a priority when transporting heavy and oversized loads, and extendable vessel bridges are designed to ensure stability throughout the journey.

- Improved Load Distribution: The extended bridge structure evenly distributes the load across the trailer, reducing stress on individual axles.

- Secure Cargo Fastening: Integrated lashing points and weight-sharing features ensure that cargo remains stable and secure during transit.

4. Cost-Effective Solution

Extendable vessel bridges provide a cost-effective alternative to purchasing multiple specialized trailers.

- Adaptable for Different Projects: Instead of investing in separate trailers, companies can use extendable bridges to accommodate varied cargo requirements.

- Compact Storage: When not in use, the retracted bridge requires less storage space, contributing to cost savings.

Applications of Extendable Vessel Bridges

Extendable vessel bridges are commonly used across several industries that require the safe transport of large and irregularly shaped cargo.

- Construction and Infrastructure

- Bridge Components: Moving large bridge sections safely and efficiently to construction sites.

- Steel Structures: Transporting long steel beams and structural elements required in major construction projects.

- Energy and Industrial Equipment

- Wind Turbine Components: Moving turbine blades and other long, delicate parts, which benefit from the bridge’s length and curvature adjustment.

- Heavy Machinery: Ideal for large transformers, power generation equipment, and refinery components.

Customization Options for Extendable Vessel Bridges

One of the key benefits of extendable vessel bridges is their customization potential, allowing companies to tailor the bridge to their specific cargo needs.

1. Cargo-Specific Design

Manufacturers like HIPOTRUK offer customization based on exact cargo specifications, including length, width, height, and weight. This ensures that the bridge meets precise transport requirements.

- Adjustable Construction Height: Commonly available options include 450 mm, 500 mm, and 650 mm, which can be tailored to match cargo height.

- Curvature Modifications: For items with irregular shapes, some bridges can adjust curvature, making them ideal for handling curved loads.

2. Removable Design and Combination Flexibility

Extendable bridges can be designed to work in combination with other modular trailer accessories.

- Removable Bridge Design: The bridge can be detached, allowing the hydraulic modular trailer to carry other types of cargo.

- Compatibility with Modular Trailers: Designed to integrate with well-known trailer brands like HIPOTRUK, ensuring flexibility across different trailer models.

3. Weight Distribution Features

For heavier cargo, some extendable vessel bridges incorporate weight-sharing beams to distribute the load effectively.

- Increased Load Capacity: Can support up to 350 tons, making it suitable for extremely heavy cargo.

- Stable Load Balance: Weight-sharing beams enhance stability by spreading the load across the trailer’s width.

Summary: The Role of Extendable Vessel Bridges in Hydraulic Modular Trailers

Extendable vessel bridges are invaluable accessories in the world of heavy transport, enhancing the versatility, efficiency, and safety of hydraulic modular trailers. With adjustable length, width, and custom features, these bridges provide a tailored solution for industries requiring the transport of oversized and irregularly shaped cargo.

Key Takeaways

- Adjustable Dimensions: Extendable vessel bridges offer length and width adjustments, ideal for oversized and long cargo.

- Enhanced Stability: Distributes weight evenly, providing a secure platform for high-center-of-gravity loads.

- Versatile Applications: Commonly used in construction, energy, and industrial sectors for large equipment.

- Cost-Effective and Customizable: Reduces the need for multiple trailers and offers customization to meet specific transport requirements.

Extendable vessel bridges represent a significant advancement in hydraulic modular trailer technology, enabling companies to efficiently and safely transport a diverse range of challenging loads across various industries.