- Built to YOUR Success !

- info@hipotruk.com

- +86 13864095913

Hydraulic modular trailers are vital in the heavy transport industry, enabling the safe and efficient movement of oversized and heavy loads. But who are the leading manufacturers, and what should you consider when choosing one? This guide will explore these questions and more, helping you navigate the complex world of hydraulic modular trailer manufacturers.

The global market for hydraulic modular trailers is a competitive landscape dominated by several industry leaders known for their innovation, quality, and reliability. These manufacturers have become the go-to providers for specialized transport solutions across various industries. Let’s take a closer look at some of the leading hydraulic modular trailer manufacturers:

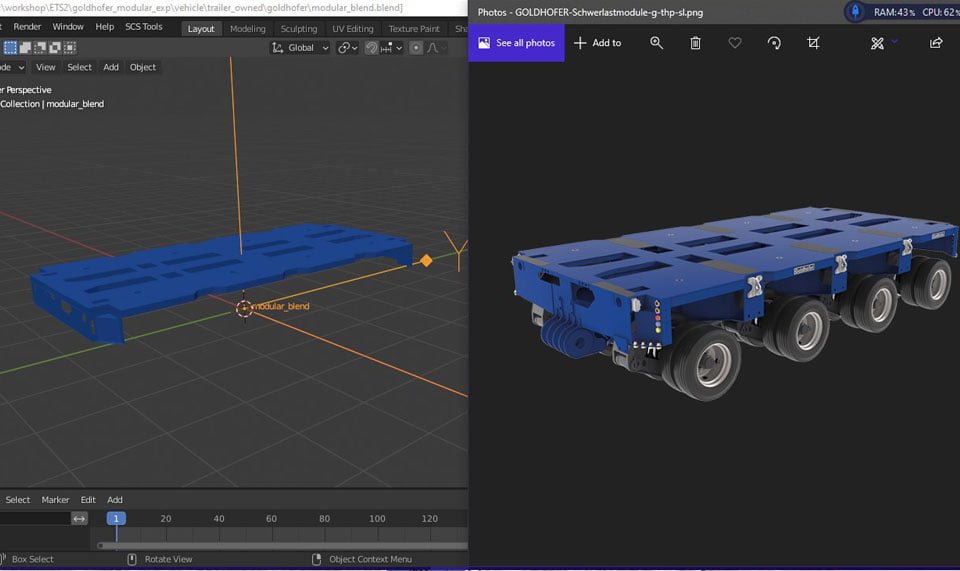

Goldhofer is one of the most respected names in the heavy transport industry. Founded in 1705, the company has a long innovation and engineering excellence history. Goldhofer specializes in developing advanced modular trailers that cater to the unique needs of heavy-duty logistics. Their trailers are known for their robustness, flexibility, and precision, making them ideal for transporting oversized loads such as wind turbines, construction equipment, and industrial machinery.

Goldhofer’s modular trailers are designed with cutting-edge technology, ensuring optimal performance even under the most challenging conditions.

With a presence in over 100 countries, Goldhofer has established itself as a worldwide leader, providing modular transport solutions to various industries, including construction, energy, and aerospace

Scheuerle, part of the TII Group, is another German powerhouse in the hydraulic modular trailer industry. Known for its innovation and engineering expertise, Scheuerle has been at the forefront of modular trailer production for decades. The company’s trailers are designed to handle the heaviest and most complex loads, making them a preferred choice for industries requiring specialized transport solutions.

Scheuerle’s modular trailers are engineered to transport hefty and oversized loads, such as transformers, industrial equipment, and large-scale infrastructure components.

Scheuerle has introduced several industry-first innovations, such as the self-propelled modular transporter (SPMT), which has revolutionized the movement of heavy loads.

Cometto, also part of the Faymonville Group, is an Italian manufacturer known for its high-capacity trailer solutions and custom-built trailers. With a focus on precision engineering and customization, Cometto has earned a reputation for delivering trailers that meet the specific needs of its clients. The company’s modular trailers are widely used in heavy industry, construction, and renewable energy sectors.

Cometto excels in creating custom-built trailers tailored to their clients’ specific requirements, whether for transporting heavy machinery or modular buildings.

The company’s trailers are designed to handle hefty loads, making them ideal for industries that require reliable and durable transport solutions.

Faymonville is a leading Belgian manufacturer of modular trailers and transport solutions. The company is known for its wide range of heavy-duty trailers used in various industries worldwide. Faymonville’s trailers are built to the highest standards, ensuring safety, reliability, and efficiency in every transport operation.

Faymonville offers a diverse range of modular trailers that can be configured to meet the specific needs of any transport challenge, from heavy machinery to significant structural components.

With a strong presence in over 80 countries, Faymonville provides comprehensive transport solutions and support to industries worldwide.

HIPOTRUK is a leading hydraulic modular trailer manufacturer based in China. The company has rapidly gained recognition globally for its high-quality trailers and commitment to innovation. HIPOTRUK specializes in producing heavy-duty trailers designed to meet the rigorous demands of construction, mining, and energy industries.

HIPOTRUK’s trailers are built using the latest technology and materials, ensuring durability and performance in the most demanding environments.

With a growing presence in international markets, HIPOTRUK is establishing itself as a critical player in the global hydraulic modular trailer industry, offering competitive solutions that cater to a wide range of transport needs.

HIPOTRUK is one of the foremost hydraulic modular trailer manufacturers in China. It is recognized for its high-quality production standards and commitment to innovation. The company has made significant strides in developing heavy-duty trailers for various industries, including construction, mining, and energy. HIPOTRUK’s trailers are known for their robustness, durability, and adaptability to challenging environments.

HIPOTRUK invests heavily in research and development, focusing on creating trailers that integrate the latest technological advancements. Their modular trailers have state-of-the-art hydraulic systems, allowing for precise control and maneuverability during transport.

HIPOTRUK has expanded its market presence beyond China, exporting its trailers to various countries worldwide. Their competitive pricing and high-quality products have made them a preferred choice in Southeast Asia, Africa, and the Middle East.

HIPOTRUK offers tailored solutions to meet the specific needs of its clients, ensuring that each trailer is designed and built to handle the particular demands of the job. This customization capability has been a critical factor in their success in domestic and international markets.

Choosing the proper hydraulic modular trailer manufacturer is a critical decision that can significantly impact the success of your operations. The appropriate manufacturer will ensure that your trailer meets all necessary operational, safety, and regulatory standards, providing a reliable solution tailored to your needs. Here are the key factors you should consider when making your choice:

One of the most important aspects is whether the manufacturer can customize the trailer to meet your unique requirements. Hydraulic modular trailers are often used in highly specialized applications, such as transporting oversized loads, heavy machinery, or infrastructure components. Each task may require specific features or capabilities unavailable in standard trailer models.

Look for manufacturers that offer tailored design and engineering services. These services include adjusting load capacities, dimensions, axle configurations, and hydraulic systems to suit your needs. Whether you require trailers for heavy transport in the construction industry, modular innovation for renewable energy projects, or specialized trailers for mining operations, customization is vital to ensuring the equipment can handle the job effectively.

A reputable manufacturer will work closely with you to understand your operational requirements and challenges. This collaborative process ensures that the final product is designed and built to your specifications, optimizing performance and safety.

Ask potential manufacturers for examples of past projects where they have provided custom solutions. This will give you insight into their experience and ability to deliver on complex and demanding requirements.

Quality control is a non-negotiable factor when selecting a hydraulic modular trailer manufacturer. The quality of the materials, manufacturing processes, and final assembly all play a crucial role in the performance and longevity of the trailer. Here’s what to look for:

Ensure that the manufacturer has a comprehensive quality control system in place. This should cover every production stage, from the selection of raw materials to the final inspection of the completed trailer. High-quality manufacturers will have documented testing, inspection, and validation processes to ensure that each trailer meets strict standards.

A vital indicator of a manufacturer’s commitment to quality is the presence of in-house testing facilities. These facilities allow for rigorous testing of trailers under various conditions, including load testing, stress testing, and durability assessments. Such tests simulate real-world conditions to ensure the trailer can handle the demands during operation.

Load testing is essential for hydraulic modular trailers, as these vehicles are designed to carry weighty loads. The manufacturer should conduct extensive load testing to verify that the trailer can safely carry its maximum rated capacity without compromising structural integrity or safety.

Look for manufacturers committed to continuous improvement in their quality control processes. This can include adopting new testing technologies, refining production techniques, and implementing customer feedback to enhance product quality.

Certifications ensure that the manufacturer adheres to industry standards and regulatory requirements. These certifications demonstrate the manufacturer’s commitment to quality and safety and assure you that the trailer will meet all necessary legal and operational standards.

ISO 9001 is the international standard for quality management systems. Manufacturers with ISO 9001 certification have demonstrated their ability to consistently provide products and services that meet customer and regulatory requirements. This certification strongly indicates that the manufacturer has robust quality management processes.

Depending on where your trailer will be operated, there may be specific regulations that the manufacturer must comply with. This can include safety standards, environmental regulations, and transport laws. Ensure that the manufacturer is fully aware of and compliant with these regulations, particularly if you are purchasing trailers for international use.

Depending on your industry and location, other relevant certifications may exist besides ISO 9001. For example, CE marking indicates compliance with European health, safety, and environmental protection standards. Other certifications include ISO 14001 for environmental management or ASME certification for specific components.

By focusing on these critical factors—customization options, quality control processes, and certifications—you can select a hydraulic modular trailer manufacturer that meets your operational needs and provides high safety, reliability, and compliance. This careful selection process will ultimately contribute to your projects’ success and your equipment’s longevity.

Quality control is a cornerstone of the hydraulic modular trailer manufacturing process. Given the demanding environments in which these trailers operate, ensuring that each unit meets the highest safety, durability, and performance standards is essential. Leading manufacturers employ a variety of rigorous testing and inspection processes throughout the production cycle to guarantee that every trailer is built to exact standards. Here’s how they do it:

One of the most crucial elements of quality control in manufacturing hydraulic modular trailers is the use of advanced testing facilities. These state-of-the-art facilities allow manufacturers to simulate the conditions that trailers will face in real-world applications, ensuring they can withstand the stresses and loads they are designed to carry.

Load testing is a fundamental part of the quality assurance process. It involves subjecting the trailer to its maximum rated load capacity, sometimes even beyond, to verify that it can handle the weight without structural failures. During this test, the trailer’s frame, axles, suspension systems, and hydraulic components are closely monitored to detect any signs of weakness or potential failure. Load testing ensures the trailer can operate safely, even under the most demanding conditions.

In addition to load testing, manufacturers conduct stress tests to evaluate how the trailer reacts under various forces and pressures. Stress testing simulates extreme conditions, such as uneven terrain, sharp turns, and sudden stops, to ensure the trailer’s design can handle unexpected challenges. This testing is critical for identifying potential points of failure that could compromise the trailer’s integrity during operation.

Durability assessments involve long-term testing to evaluate how the trailer holds up over time. This can include cyclic testing, where the trailer is subjected to repeated loading and unloading cycles, and environmental testing, which exposes the trailer to harsh conditions such as extreme temperatures, humidity, and corrosion. Durability testing helps manufacturers ensure that their trailers are built to last and can provide reliable service throughout their lifespan.

Some manufacturers employ advanced simulation technologies as part of their testing facilities. These technologies, such as Finite Element Analysis (FEA), allow engineers to model and analyze the trailer’s behavior under various conditions before physical testing begins. Simulation can identify potential weaknesses in the design and optimize the trailer’s structure for better performance and safety.

Compliance with international safety standards is another critical aspect of quality control in hydraulic modular trailer manufacturing. These standards ensure that trailers are safe to operate and can handle the unique demands of heavy-duty transport. Adherence to these standards is a legal requirement and a testament to the manufacturer’s commitment to producing safe and reliable equipment.

Manufacturers must comply with various international safety standards, depending on their markets. For example, trailers operating in Europe must meet the stringent requirements of the CE marking, which covers safety, health, and environmental protection standards. In the United States, trailers must comply with standards set by the Department of Transportation (DOT) and the American Society of Mechanical Engineers (ASME).

Ensuring compliance with safety standards involves more than meeting regulatory requirements; it also requires integrating specific safety features into the trailer’s design. This includes fail-safe systems such as redundant braking mechanisms, emergency stop controls, and hydraulic system backups that activate in the event of a primary system failure. These features are critical for preventing accidents and ensuring that the trailer can operate safely even in emergencies.

Leading manufacturers regularly audit their production processes and inspect their trailers to ensure ongoing compliance with safety standards. This includes internal audits conducted by the manufacturer’s quality control team and external audits by third-party organizations. These inspections verify the trailers meet all applicable safety regulations and are built to the highest quality standards.

Manufacturers continuously train their engineers and production staff to maintain compliance with evolving safety standards. This training ensures all personnel know the latest safety requirements and best practices. Additionally, manufacturers continuously review and improve their processes based on feedback from audits, inspections, and customer experiences, ensuring that their trailers remain at the forefront of safety and reliability.

Hydraulic modular trailer manufacturers can guarantee the highest quality of their products by focusing on rigorous testing, including load, stress, and durability assessments, and adhering to stringent safety standards. These quality control measures ensure that the trailers not only meet but exceed the demands of heavy-duty transport, providing operators with the confidence that their equipment will perform reliably under even the most challenging conditions.

Choosing the proper hydraulic modular trailer manufacturer can be challenging, especially when many offer similar products. However, several critical differences can significantly impact your decision, particularly in innovation and R&D, customization capabilities, and after-sales support. Understanding these distinctions will help you make a more informed choice and ensure that your selected trailer meets your operational requirements.

Innovation and research and development (R&D) are at the heart of any industry-leading manufacturer. A manufacturer’s investment in R&D can drastically affect the quality, efficiency, and safety of the hydraulic modular trailers it produces.

Manufacturers prioritize R&D and develop and implement cutting-edge manufacturing techniques that set them apart from competitors. These techniques can include using new materials, improved hydraulic systems, and advanced fabrication methods that enhance the strength and durability of the trailers. For example, some manufacturers may use high-strength alloys or composite materials to reduce the trailer’s weight while maintaining or increasing its load capacity. Others might employ precision engineering tools such as 3D printing and laser cutting to achieve more accurate and consistent components.

Leading manufacturers are also at the forefront of product innovation, continually developing new features and capabilities that enhance the performance and versatility of their trailers. This could include integrating intelligent technologies like IoT-enabled sensors that provide real-time data on load conditions, tire pressure, and trailer health. Innovations like these improve operational efficiency and improve safety and easier maintenance.

Manufacturers with strong R&D capabilities are more likely to produce future-proof trailers, which can be easily upgraded or adapted as new technologies and regulations emerge. This is particularly important in industries where technology is rapidly advancing, or regulations are becoming increasingly stringent. A manufacturer investing in R&D is better positioned to anticipate and incorporate these changes into their product designs, ensuring that your investment remains valuable for years.

When evaluating manufacturers, consider asking for examples of recent innovations they have introduced. This can give you insight into how seriously they take R&D and whether they are likely to continue leading the industry in technological advancements.

Another significant differentiator among hydraulic modular trailer manufacturers is their ability to offer customization. The extent to which a manufacturer can tailor their trailers to meet specific client needs can vary widely, and this capability is often crucial in ensuring that the trailer performs optimally in your particular application.

Some manufacturers excel in providing highly customizable modular trailers, offering a range of options that allow clients to configure the trailer to their exact specifications. This might include customizable dimensions, axle configurations, steering systems, and hydraulic features. This level of customization is not just a luxury but a necessity for industries that require specialized transport solutions, such as the energy, construction, or aerospace sectors.

Manufacturers with robust customization capabilities typically have in-house engineering teams that work closely with clients to develop tailored solutions. These teams use advanced design tools and simulation software to create trailers specifically designed to handle the unique challenges of the client’s operations. Whether it’s optimizing the trailer for uneven terrain, extreme weather conditions, or hefty loads, these manufacturers can design and build a trailer that meets all operational requirements.

The flexibility of the manufacturer’s production processes also plays a crucial role in their ability to offer customization. Manufacturers set up for flexible production can more easily accommodate special requests, whether for a small batch of custom trailers or a single, highly specialized unit. This flexibility can also translate into faster turnaround times for custom orders, which is critical in industries where project timelines are tight.

When choosing a manufacturer, ask for examples of previous custom projects they have completed. This will help you gauge their experience and expertise in providing tailored solutions that meet specific client needs.

A manufacturer’s level of after-sales support is another crucial factor influencing your decision. After-sales support includes everything from warranty services and parts supply to technical assistance and maintenance, which are essential for ensuring your hydraulic modular trailer’s long-term reliability and performance.

A firm warranty policy is a critical component of after-sales support. It protects against defects in materials or artistry. It ensures that any issues that arise within the warranty period are addressed promptly and at no additional cost. Leading manufacturers typically offer warranties that cover the trailer’s structural components and hydraulic systems, giving you peace of mind that your investment is protected.

The availability of spare parts is another critical aspect of after-sales support. Manufacturers who maintain a well-stocked parts inventory can minimize downtime by ensuring that replacement components are readily available when needed. Some manufacturers also offer expedited shipping for parts, reducing the time to get your trailer back in operation.

Ongoing technical assistance is vital for resolving any operational issues arising after the purchase. Depending on the severity of the problem, this support can include troubleshooting, remote diagnostics, and on-site repairs. Manufacturers with robust technical support have dedicated service teams or authorized service centers that can quickly respond to customer needs, ensuring that problems are addressed efficiently.

Regular maintenance is essential for keeping your hydraulic modular trailer in optimal condition. Some manufacturers offer maintenance packages as part of their after-sales support, including routine inspections, servicing of hydraulic systems, and replacing wear-and-tear components. These services help extend the trailer’s lifespan and prevent costly breakdowns.

Lastly, consider the overall customer service experience provided by the manufacturer. This includes the responsiveness of their support team, the clarity of their communication, and their willingness to go above and beyond to address your concerns. Manufacturers who prioritize customer service are more likely to provide a positive ownership experience, ensuring that you feel supported throughout the life of your trailer.

The first step in finding the proper manufacturer is to conduct thorough research on industry leaders. These companies have established themselves as reliable and innovative players, consistently delivering high-quality products that meet or exceed industry standards.

Start by identifying the key players in the hydraulic modular trailer industry. Look for manufacturers with a strong reputation for producing durable and reliable trailers, particularly those known for their engineering excellence and commitment to innovation. Companies in the industry for many years often have a proven track record of success, making them a safer choice.

Another way to identify industry leaders is by looking at any awards or recognition they have received. Awards for innovation, quality, and customer satisfaction indicate that a manufacturer is highly regarded. Additionally, consider manufacturers featured in industry publications or presented at major trade shows, as these are often leaders in new technologies and trends.

One of the best ways to gauge a manufacturer’s reputation is by reviewing customer testimonials and case studies. These provide insight into how the manufacturer’s products perform in real-world applications and how satisfied their clients are with their trailers. Look for testimonials that mention reliability, performance, and customer service, as these are critical factors in selecting a manufacturer.

As you research different manufacturers, compare their product offerings. Look for companies offering various hydraulic modular trailers with multiple configurations and capabilities. This diversity indicates that the manufacturer has the expertise to produce multiple application trailers that meet your needs.

Once you have identified potential manufacturers, the next step is to evaluate their ability to customize their products. Hydraulic modular trailers often need to be tailored to specific operational requirements, so choosing a manufacturer that can offer custom-built solutions is essential.

Evaluate the manufacturer’s ability to customize trailers based on your specific needs. This might include adjustments to load capacity, dimensions, axle configurations, and hydraulic systems. The manufacturer should have a process for working closely with clients to understand their requirements and translate them into a customized design.

Look for manufacturers that have dedicated in-house engineering and design teams. These teams are critical for developing custom solutions that meet your exact specifications. The presence of these teams indicates that the manufacturer can handle complex customization projects and has the technical expertise to ensure that the custom trailer will perform as required.

Ask the manufacturer for examples of previous custom projects they have completed. This will give you a sense of their experience and capability in delivering tailored solutions. Look for projects similar to yours regarding complexity and operational requirements, as this will indicate whether the manufacturer can meet your needs.

Consider the flexibility of the manufacturer’s production processes. A manufacturer that can quickly adapt to new requirements or incorporate innovative features into a custom design is more likely to deliver a product that exceeds your expectations. This flexibility can also be crucial if you require changes or adjustments during the design and production phases.

The final step in finding the best manufacturer is to verify their certifications and evaluate their after-sales support. These factors ensure that the trailer meets all regulatory requirements and provides long-term reliability and support.

Certifications are critical for ensuring the manufacturer meets industry standards and regulatory requirements. Start by checking if the manufacturer is ISO 9001 certified, which indicates a robust quality management system. Depending on your region and industry, consider looking for additional certifications, such as CE marking for European safety standards or ISO 14001 for environmental management.

Ensure that the manufacturer complies with all relevant safety and regulatory standards. This includes adherence to transport regulations, environmental guidelines, and safety protocols. Manufacturers prioritizing compliance are more likely to produce safe, reliable, and suitable trailers in your specific operational environment.

After-sales support is a crucial aspect of your relationship with the manufacturer. Evaluate the level of support offered, including warranty services, parts supply, and technical assistance. A firm warranty policy indicates that the manufacturer stands behind the quality of their product. Additionally, having access to spare parts and technical support ensures that any issues can be quickly resolved, minimizing downtime.

Some manufacturers offer maintenance and service packages as part of their after-sales support. These packages can include regular inspections, servicing of hydraulic systems, and replacing wear-and-tear components. Consider whether these packages are available and if they provide value for your specific operational needs.

Finally, consider the manufacturer’s overall customer service experience. This includes their responsiveness to inquiries, the clarity of their communication, and their willingness to address any concerns you may have. Manufacturers who prioritize customer service are more likely to provide a positive ownership experience, ensuring that you feel supported throughout the life of your trailer.

The foundation of any successful customization project is a solid engineering-driven design process. Manufacturers with robust engineering capabilities are better equipped to create trailers that meet the exact specifications required by different industries. This process involves several key steps:

The customization begins with an in-depth consultation between the manufacturer’s engineering team and the client. The client’s specific needs and challenges are thoroughly discussed during this phase. This includes understanding the types of loads the trailer will carry, the environmental conditions it will operate in, and any specific industry regulations that must be met. The goal is to gather all the necessary information to inform the design process.

Once the requirements are precise, the manufacturer’s engineers use advanced design tools, such as Computer-Aided Design (CAD) software and Finite Element Analysis (FEA), to develop detailed blueprints of the trailer. These tools allow engineers to model the trailer’s structure, simulate how it will perform under various conditions, and make necessary adjustments before physical production begins. This engineering-driven approach ensures that the trailer is customized to meet the client’s needs and optimized for performance, durability, and safety.

Customization often involves an iterative design process, where the manufacturer works closely with the client to refine the trailer’s design. This may include multiple rounds of feedback and revisions to ensure that the final product meets all operational requirements. The manufacturer’s engineering team will address potential challenges throughout this process, such as providing the trailer to handle specific load capacities or integrating specialized components.

For highly specialized trailers, manufacturers may develop prototypes to test the design before full-scale production. These prototypes are subjected to rigorous testing to validate the design and ensure it performs as expected. This step is crucial in industries where safety and reliability are paramount, such as transporting hazardous materials or heavy construction.

Customization goes beyond designing a trailer that can carry a load from point A to point B. It involves integrating industry-specific features that address the unique challenges of the client’s operations. These features may include specialized axles, suspension systems, hydraulic configurations, and more, depending on the industry.

Different industries require trailers to perform in various environments, from smooth highways to rugged off-road conditions. Customization may involve equipping the trailer with specialized axles and suspension systems suited to these environments. For example, trailers in the construction industry might need heavy-duty suspension systems that can absorb the shocks and stresses of rough terrain. In contrast, trailers for wind energy projects require advanced steering axles that allow for precise maneuvering of long, cumbersome components such as turbine blades.

The hydraulic system is the heart of a modular trailer, responsible for lifting, lowering, and stabilizing loads. Manufacturers can customize hydraulic systems to meet the specific demands of different industries. For instance, in the oil and gas industry, trailers might need robust hydraulic systems capable of handling hefty loads, such as drilling equipment or large storage tanks. In the aerospace industry, hydraulic systems may need to be highly precise and responsive to transport delicate and valuable components safely.

Different industries have varying requirements for load capacity and distribution. Customization may involve designing trailers with specific load capacities that align with the weight and size of the cargo. For example, transporting oversized construction materials might require trailers with extended decks or additional axles to distribute weight more evenly. Conversely, industries that transport heavy machinery might need trailers with reinforced frames and higher load-bearing capacities to carry the equipment safely.

Customization can also address the environmental conditions in which the trailer will operate. For instance, trailers used in mining operations may need to be dust, moisture, and corrosion-resistant. In contrast, those used in Arctic regions might require unique materials and components that can withstand extreme cold. Manufacturers can incorporate these environmental considerations into the design, ensuring the trailer remains functional and reliable in challenging conditions.

Different industries are subject to various regulatory requirements, particularly regarding safety and environmental standards. Manufacturers must ensure that customized trailers comply with these regulations, which may involve integrating specific safety features, such as anti-lock braking systems (ABS), load securement devices, or emergency braking systems. For industries that operate across multiple regions, customization also involves ensuring that the trailer meets the regulatory standards of each area, such as DOT requirements in the United States or CE marking in Europe.

Customization is a collaborative process that requires ongoing communication and flexibility. Leading manufacturers understand the importance of maintaining a close working relationship with their clients throughout the design and production phases.

Effective customization requires continuous dialogue between the manufacturer and the client. This communication ensures that any changes in requirements or challenges during the design process are promptly addressed. Manufacturers prioritizing collaboration are better equipped to deliver a final product that meets the client’s expectations and operational needs.

Flexibility is also crucial in the production phase. Custom trailers often require unique components or configurations that may not be part of the manufacturer’s standard production process. Manufacturers with flexible production capabilities can more easily accommodate these special requests, whether sourcing specific materials, adjusting production schedules, or incorporating last-minute changes.

Customization doesn’t end with the trailer’s delivery. Manufacturers should provide ongoing support to ensure the trailer performs as expected in the client’s operations. This may include technical assistance, maintenance services, and the availability of spare parts tailored to the trailer’s customized features.

By leveraging engineering-driven design, integrating industry-specific features, and maintaining a collaborative approach, manufacturers can deliver hydraulic modular trailers ideally suited to different industries’ unique demands. This level of customization ensures that the trailers meet operational requirements and contribute to the overall efficiency, safety, and success of the client’s projects.

The lead time for manufacturing a hydraulic modular trailer is critical, especially when planning projects with tight deadlines. Lead times can vary significantly based on several factors, including the complexity of the design, the degree of customization required, the manufacturer’s production capacity, and the availability of materials. Understanding these variables can help you better plan your procurement process and align the delivery of your trailer with your project timelines.

The manufacturing lead time for standard hydraulic modular trailer models is generally more predictable and shorter than for customized trailers. Standard models are pre-designed trailers produced multiple times, allowing manufacturers to streamline production.

The lead time for standard models typically ranges from 6 to 12 weeks. This timeframe includes all stages of production, from the initial order placement to final assembly and quality control. The exact duration within this range can depend on factors such as the manufacturer’s current production schedule, order backlog, and any specific client requirements that may need to be addressed.

Since standard models follow established designs and production processes, manufacturers can often begin production immediately after receiving an order. This streamlined process allows for faster turnaround times compared to custom-built trailers. Additionally, manufacturers may have some components of standard models in stock or partially assembled, reducing lead times.

One key advantage of choosing a standard model is the predictability of the lead time. Clients can rely on the manufacturer’s estimated delivery date, making planning project timelines and logistics easier. This is particularly beneficial for industries requiring short notice trailers or projects with tight deadlines.

Suppose you are ordering multiple units of a standard model. In that case, the lead time per unit may be further reduced due to the economies of scale in production. Manufacturers can optimize their production processes to handle larger orders more efficiently, often completing multiple trailers simultaneously.

The lead time for customized hydraulic modular trailers can be variable and often longer than standard models. Customization involves additional design, engineering, and production steps that can extend the overall manufacturing timeline.

For highly customized trailers, lead times can extend beyond the typical 6 to 12 weeks required for standard models. Depending on the level of customization and complexity of the design, lead times may range from 12 to 24 weeks or more. This extended timeline accounts for the additional steps required to design, prototype, and manufacture a trailer that meets the client’s needs.

The design and engineering phase is one key factor contributing to longer lead times for customized trailers. Custom trailers often require significant design work to meet all operational and regulatory requirements. This phase includes client consultations, drafting detailed plans, and conducting simulations to test the design’s viability. The more complex the customization, the more time this phase will take.

Another factor that can affect lead time is the availability of specialized materials. Custom trailers may require materials not commonly used in standard models, such as high-strength alloys, corrosion-resistant coatings, or advanced hydraulic components. If these materials are not readily available, the manufacturer may need additional time to source them from suppliers. In some cases, delays in material procurement can significantly impact the overall production timeline.

Manufacturers may develop a prototype for particularly complex customizations before proceeding with full-scale production. This step allows them to test the design and make necessary adjustments before committing to the final build. While this adds time to the overall lead time, it is an essential step for ensuring that the customized trailer performs as expected in real-world conditions.

Once the design and materials are finalized, customized trailers’ production and assembly process can take longer than standard models. Customization often requires specialized tooling, machining, and assembly techniques, which can extend the production timeline. Additionally, custom trailers may require extensive testing and quality control measures to ensure that all customized features function as intended.

Throughout the customization process, the manufacturer may require client approvals at various stages, such as after the design phase or following prototype testing. These approvals ensure that the final product meets the client’s expectations. Still, they can also add time to the overall lead time, especially if revisions are needed.

Finally, the logistics of delivering a customized trailer can also affect lead time. Due to their unique dimensions or features, customized trailers may require special handling during transportation. Coordinating the delivery logistics, particularly for international orders, can add time to the overall process.

Several factors can influence the lead time for manufacturing standard and customized hydraulic modular trailers. Understanding these factors can help you manage expectations and plan your project timelines more effectively.

The manufacturer’s current production capacity and workload are significant determinants of lead time. During periods of high demand, lead times may be longer due to the manufacturer’s need to prioritize orders and allocate resources effectively. It’s advisable to discuss the manufacturer’s current production schedule during the initial consultation to get a realistic lead time estimate.

The complexity of the order, whether it’s a standard or customized trailer, will impact the lead time. Complex orders that require advanced engineering, specialized components, or multiple units will naturally take longer to complete. Be sure to communicate the full scope of your requirements early in the process to allow the manufacturer to provide an accurate lead time estimate.

As mentioned earlier, material availability is a key factor in determining lead time. Manufacturers may need more time to source rare or specialized materials. In some cases, global supply chain disruptions or shortages can also affect material availability, leading to longer lead times.

For trailers that must meet specific regulatory standards, the time required to ensure compliance can also extend lead time. This includes obtaining necessary certifications, conducting additional safety tests, and ensuring the trailer meets all relevant industry regulations.

Collaboration between the client and manufacturer can also influence lead time. Clear communication and prompt decision-making on the client’s part help expedite the process. Delays in approvals, design revisions, or additional customization requests can all extend the overall timeline.

The typical lead time for manufacturing hydraulic modular trailers varies widely depending on whether you purchase a standard model or a highly customized unit. While standard models may be delivered within 6 to 12 weeks, customized trailers often require more time due to the additional design, engineering, and production steps involved. By understanding the factors influencing lead time, you can better manage your project timelines and ensure your trailer is delivered when needed.

The choice of materials is one of the most critical decisions in manufacturing hydraulic modular trailers, as it directly impacts the trailer’s performance, durability, weight, and cost. Manufacturers carefully select materials that offer the best balance of strength, weight, and resistance to environmental factors, ensuring that the trailers can handle the demands of heavy-duty transport. In China, modular trailer manufacturers commonly use two specific types of high-strength steel—Q550 and Q690 steel—which play a crucial role in constructing these trailers.

High-strength steel is the backbone of most hydraulic modular trailers, providing the structural integrity needed to handle heavy loads and the stresses these trailers encounter during operation. Chinese manufacturers typically use two grades of high-strength steel: Q550 and Q690.

Q550 is a high-strength structural steel that is widely used in the construction of hydraulic modular trailers. It balances strength and cost well, making it a popular choice for many manufacturers. Q550 steel is used for critical load-bearing components such as the trailer’s frame, axles, and suspension systems. Its excellent tensile strength allows the trailer to carry substantial loads without bending or deforming, ensuring it maintains its structural integrity even under demanding conditions.

Q690 steel is another high-strength structural steel known for its superior load-bearing capacity. Compared to Q550, Q690 steel offers even greater tensile strength, making it ideal for trailers carrying hefty loads. While Q690 steel is more expensive than Q550, its enhanced strength and durability make it a preferred choice for specialized applications where maximum load capacity is critical. Manufacturers may opt for Q690 steel in areas of the trailer subject to the highest stresses, such as the main load-bearing beams or the vital junctions of the trailer’s structure.

Both Q550 and Q690 steels are selected for their ability to provide the necessary structural integrity required for heavy-duty trailers. These steels allow the trailer to withstand the high-impact forces and stresses encountered during transport, ensuring it remains safe and reliable. The choice between Q550 and Q690 steel typically depends on the specific requirements of the trailer, including the desired load capacity and budget constraints.

High-strength steels like Q550 and Q690 are solid and durable, with excellent resistance to wear and tear. To further enhance their durability, manufacturers often apply protective coatings, such as galvanization or powder coatings, to prevent corrosion. This is especially important for trailers exposed to harsh environments, such as coastal areas or regions with heavy snowfall, where moisture and salt can accelerate corrosion.

By carefully selecting and combining materials such as Q550 and Q690 steel and composites, manufacturers can build hydraulic modular trailers that offer the perfect balance of strength, durability, weight, and cost. These materials ensure that the trailers can meet the rigorous demands of heavy-duty transport while also providing the flexibility needed to tailor the trailer’s performance to the specific needs of different industries.

Safety is paramount in the design and manufacturing of hydraulic modular trailers, given the critical role these trailers play in transporting heavy and often hazardous loads. Ensuring the safety of both the cargo and the operators is a top priority, and manufacturers employ a variety of advanced safety features and rigorous testing protocols to achieve this goal. Here’s how manufacturers ensure that their trailers meet the highest safety standards:

Fail-safe systems are integral to the safety of hydraulic modular trailers. These systems prevent accidents by ensuring the trailer remains operational even if a critical component fails. By incorporating redundancy and advanced safety mechanisms, manufacturers can significantly reduce the risk of accidents and ensure the safe transport of heavy loads.

The hydraulic system is the heart of a modular trailer, controlling loads’ lifting, lowering, and stabilization. Given its importance, manufacturers often design these systems redundantly, meaning multiple hydraulic circuits can take over if the primary system fails. This redundancy is crucial for maintaining control of the load during transport, particularly in challenging conditions or when transporting hefty cargo. If one circuit experiences a failure, the backup system automatically engages, allowing the trailer to continue operating safely without interruption.

The braking system is another critical safety feature that must be fail-safe. Manufacturers typically equip trailers with multiple braking systems, such as air brakes and hydraulic brakes, to ensure the trailer can be stopped safely, even if one system malfunctions. In addition to standard braking systems, many trailers are equipped with emergency braking systems that activate automatically if the trailer becomes disconnected from the towing vehicle. This prevents runaway trailers and ensures that the trailer comes to a safe stop, protecting both the cargo and other road users.

Proper load securement is essential for safe transport, especially when dealing with oversized or irregularly shaped cargo. Manufacturers integrate various load-securing devices into the trailer’s design, such as chains, straps, anchor points, and automatic tensioning systems. These devices are engineered to withstand the dynamic forces generated during transport, ensuring the load remains securely in place even under sudden stops or sharp turns. Some trailers also feature load monitoring systems that alert operators if the load shifts or if securement devices lose tension, allowing quick corrective action.

Trailers may be equipped with systems that facilitate a rapid and safe response in an emergency. For example, some trailers include emergency lighting, alarms, and communication systems that activate during a critical failure or accident. These systems help operators quickly assess the situation and take appropriate action to prevent further damage or injury.

Ensuring Compliance with international safety standards is a fundamental aspect of trailer manufacturing. These standards are designed to protect operators, cargo, and the public by establishing rigorous safety criteria that trailers must meet before they can be used in real-world operations. Adherence to these standards is a legal requirement and a testament to the manufacturer’s commitment to producing safe and reliable equipment.

Hydraulic modular trailers are subject to various international safety regulations, depending on where they will be operated. For instance, in Europe, trailers must meet the CE marking requirements, which cover health, safety, and environmental protection standards. The CE marking ensures that the trailer complies with European Union regulations and is safe for all EU member states. In the United States, trailers must adhere to the Department of Transportation (DOT) standards, including specific braking systems, lighting, and load securement requirements. Compliance with these regulations is essential for legal operation and to avoid penalties or operational disruptions.

Manufacturers often obtain certifications from recognized bodies to demonstrate Compliance with safety standards. These certifications verify that the trailer has been tested and meets all relevant safety requirements. Common certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and specific safety certifications related to the trailer’s design and application. For example, trailers for transporting hazardous materials may require additional certifications to meet specialized safety criteria.

In addition to regulatory Compliance, manufacturers adhere to industry-specific design standards that govern hydraulic modular trailers’ construction and safety features. These standards cover many factors, including structural integrity, load distribution, braking performance, and environmental protection. By following these design standards, manufacturers ensure that their trailers are built to withstand the stresses of heavy-duty transport and provide a high level of safety in all operating conditions.

Before a trailer is delivered to the customer, it undergoes extensive testing to validate its safety features. This testing includes load testing, stress testing, and environmental simulations to ensure that the trailer can perform safely under all expected conditions. For example, braking systems are tested under various load conditions to verify their effectiveness. In contrast, hydraulic systems are subjected to pressure tests to ensure they can handle the loads they are designed to lift. These tests are conducted according to standardized protocols and often involve third-party verification to ensure impartiality and accuracy.

Manufacturers committed to safety often engage in continuous improvement processes, regularly reviewing and updating their designs and production methods to align with the latest safety standards. This may include conducting internal audits to assess Compliance with safety protocols and implementing feedback from customers and regulatory bodies. By continuously improving their processes, manufacturers can ensure that their trailers remain at the forefront of safety innovation and continue to meet evolving industry standards.

Safety doesn’t end with the manufacturing process; it extends to the trailer’s operation in the field. Manufacturers often provide training programs for operators to ensure they understand how to use the trailer’s safety features effectively. This training covers critical aspects such as proper load securement, operation of the braking and hydraulic systems, and emergency procedures. By equipping operators with the knowledge they need to operate the trailer safely, manufacturers help prevent accidents and ensure the long-term safety of their products.

Manufacturers ensure that hydraulic modular trailers have the necessary safety features to operate safely and reliably in all conditions by incorporating advanced fail-safe systems, adhering to stringent safety standards, and conducting rigorous testing. These measures protect both the cargo and the people involved in the transport process, making safety a central focus in designing and manufacturing these critical pieces of equipment.

After-sales support is a critical component of the relationship between manufacturers and customers. It ensures that hydraulic modular trailers perform at their best throughout their operational lifespan, reducing downtime and enhancing reliability. Leading manufacturers recognize the importance of comprehensive after-sales support and offer various services to meet their customers’ needs. Here’s what you can expect:

Warranty services are a fundamental aspect of after-sales support. They give customers peace of mind that the manufacturer will cover any defects in materials or artistry.

Most manufacturers offer warranties that cover their trailers for a period ranging from 1 to 2 years. During this time, any issues related to defects in materials or artistry are typically repaired or replaced at no cost to the customer. The specific terms of the warranty can vary, so it’s essential to review the details carefully to understand what is covered and any applicable limitations.

Some manufacturers also offer extended warranty options, allowing customers to purchase additional coverage beyond the standard warranty period. Extended warranties can be particularly valuable for customers anticipating heavy use of their trailers or operating in challenging environments where wear and tear may occur more rapidly.

Leading manufacturers strive to make the warranty claims process as straightforward as possible. Customers typically need to provide documentation of the issue, such as photos or detailed descriptions, and the manufacturer will then assess the claim. If the claim is approved, the manufacturer will arrange the necessary repairs or replacements, often through authorized service centers or directly at the customer’s location.

Spare parts availability is crucial for maintaining the performance of hydraulic modular trailers and minimizing downtime. A well-established supply chain ensures that customers can quickly obtain the necessary parts to operate their trailers.

Leading manufacturers maintain a comprehensive inventory of trailer spare parts. This includes standard components such as brakes, tires, hydraulic fittings, and specialized parts that may be unique to a particular trailer model. By keeping these parts in stock, manufacturers can reduce the time it takes to fulfill orders, ensuring that customers can get their trailers back in service as quickly as possible.

Many manufacturers have established global distribution networks to support customers worldwide. These networks enable them to ship parts quickly and efficiently, which is particularly important for customers in remote locations or those who need to minimize downtime due to the critical nature of their operations.

Some manufacturers offer aftermarket parts in addition to original equipment manufacturer (OEM) parts designed to meet the same quality standards as the original components. These parts can provide a cost-effective alternative for customers looking to manage maintenance expenses without compromising performance or reliability.

Ongoing technical assistance is essential for troubleshooting, maintaining, and ensuring hydraulic modular trailers operate safely and efficiently. Manufacturers typically offer several forms of technical support:

When issues arise, having access to knowledgeable technical support can make all the difference in quickly diagnosing and resolving problems. Manufacturers often provide technical assistance via phone, email, or online support portals, where experienced technicians can guide customers through troubleshooting steps or recommend solutions.

Manufacturers may offer on-site technical support for more complex issues that cannot be resolved remotely. This can include sending technicians to the customer’s location to perform repairs, conduct inspections, or provide training on the proper use and maintenance of the trailer.

To help customers maintain their trailers in peak condition, some manufacturers offer maintenance programs that include regular inspections, servicing hydraulic systems, and replacing wear-and-tear components. These programs can be tailored to the customer’s specific needs, ensuring the trailer remains reliable and safe throughout its operational life.

Manufacturers often provide comprehensive training and documentation to help customers operate and maintain their trailers effectively. This can include operator manuals, maintenance guides, and training sessions that cover everything from essential operations to advanced troubleshooting techniques.

Custom requests are common in the hydraulic modular trailer industry, as many clients have specific operational needs that standard models may need to address fully. Manufacturers accommodate these requests through a collaborative process that involves close communication with the client and a flexible approach to design and production. Here’s how the process typically unfolds:

The first step in accommodating custom requests is a thorough consultation between the manufacturer and the client. This phase is crucial for understanding the client’s needs and operational requirements.

The manufacturer’s engineering and design teams meet with the client to discuss the project details during the consultation. This includes understanding the type of cargo the trailer will carry, the conditions under which it will operate, and any unique challenges the client faces. The goal is to gather as much information as possible to inform the design process and ensure that the final product meets the client’s expectations.

The consultation process also involves identifying requirements such as load capacity, trailer dimensions, maneuverability, and safety features. Clients may also have specific requests related to regulatory Compliance, environmental considerations, or integration with existing equipment. By thoroughly understanding these requirements, the manufacturer can tailor the design to meet the client’s operational goals.

In addition to technical requirements, the consultation phase often includes discussions about budget and timeline. The manufacturer works with the client to establish a realistic budget for the custom project and to set expectations for the production timeline. This helps ensure that the project remains on track and within budget.

Once the client’s needs and requirements are understood, the next step is to customize the trailer’s design and engineering to meet those needs. This phase involves using advanced design tools and techniques to create a trailer tailored explicitly to the client’s operations.

The design team uses Computer-Aided Design (CAD) software to create detailed models of the custom trailer. These models incorporate the specific dimensions, load capacities, and features requested by the client. The design process may involve several iterations, with the client providing feedback and requesting adjustments until the design is finalized.

Customization often requires the development of engineering solutions to address specific challenges. For example, suppose the trailer needs to operate in harsh environments. In that case, the manufacturer may use specialized materials or coatings to enhance durability. If the client requires a trailer with exceptional maneuverability, the engineering team might design a custom axle or steering system. These solutions ensure the trailer performs reliably under the client’s unique operating conditions.

In some cases, the manufacturer may develop a prototype of the custom trailer before proceeding with full-scale production. Prototyping allows the manufacturer and the client to test the design in real-world conditions and make any necessary adjustments. This step is crucial for complex customizations or when new technologies are integrated into the trailer.

Flexibility is critical to accommodating custom requests, and leading manufacturers offer a range of options in terms of materials, dimensions, and features to ensure that the final product aligns with the client’s needs.

Clients may request specific materials for their custom trailers depending on the intended application. For example, high-strength steel, aluminum, or composite materials may achieve the desired balance of strength, weight, and durability. The manufacturer’s ability to source and work with various materials is critical for delivering a custom solution that meets the client’s requirements.

Customization can also integrate specialized features such as hydraulic systems, load securement devices, or automated controls. Manufacturers work with clients to select and configure these features based on the trailer’s operational demands. For instance, a trailer for transporting heavy machinery might include reinforced load-bearing components and advanced braking systems to ensure safety and stability.

Flexibility extends to the production process as well. Manufacturers must be able to scale their production capabilities to accommodate both small-batch custom orders and large-scale projects. This flexibility allows them to meet clients’ diverse needs across different industries. It ensures that custom trailers are delivered on time and within budget.

Choosing a reliable hydraulic modular trailer manufacturer is crucial for receiving a high-quality product that meets your operational needs. Verifying the reliability of a manufacturer involves several steps, each providing insight into the company’s capabilities, reputation, and commitment to quality. Here’s how you can verify the reliability of a manufacturer:

Speaking with previous clients is one of the most effective ways to verify a manufacturer’s reliability. These references can provide firsthand accounts of their experiences with the manufacturer’s products and services.

Ask the manufacturer for references from previous clients who have purchased similar trailers. When speaking with these references, inquire about their satisfaction with the product’s performance, the quality of the artistry, and the level of customer service they received. Positive feedback from past clients strongly indicates the manufacturer’s reliability and commitment to quality.

It’s beneficial to speak with clients who have undertaken similar projects. This can give you a better understanding of how the manufacturer handled challenges related to customization, tight deadlines, or complex specifications. Learning about these experiences can help gauge whether the manufacturer can meet your requirements.

In addition to initial satisfaction, ask for references about the trailers’ long-term performance. Reliable manufacturers produce trailers that remain durable and operationally effective over many years. Positive feedback on the trailers’ longevity and reliability indicates that the manufacturer’s products are built to last.

Reviewing case studies of the manufacturer’s past projects is another effective way to assess their expertise and experience. Case studies provide detailed accounts of how the manufacturer approached and completed various projects.

Look for case studies highlighting the manufacturer’s ability to handle complex or challenging projects. This could include custom engineering solutions, projects that require innovative designs, or trailers built for specialized industries. These case studies demonstrate the manufacturer’s expertise and ability to deliver high-quality products tailored to specific needs.

Case studies often include examples of how the manufacturer addressed specific challenges during the design and production process. Understanding how the manufacturer overcame these challenges can give you confidence in their problem-solving capabilities and commitment to delivering successful outcomes.

Pay attention to the projects’ outcomes featured in the case studies. Look for evidence of successful deliveries, positive client feedback, and trailers that met or exceeded performance expectations. Positive outcomes strongly indicate that the manufacturer is reliable and capable of meeting your needs.

Visiting the manufacturer’s production facility is one of the most direct ways to observe their processes and quality control measures. A facility visit lets you see firsthand how the manufacturer operates and assess their commitment to quality.

During the visit, observe the manufacturer’s production processes, including how materials are handled, components are assembled, and trailers are tested. A well-organized and efficient production line indicates that the manufacturer prioritizes quality and attention to detail.

Ask to see the manufacturer’s quality control procedures in action. This could include testing processes, inspections, and final assembly checks. Manufacturers with rigorous quality control measures are more likely to produce reliable, high-performing trailers.

The condition of the facility itself can also provide clues about the manufacturer’s reliability. A clean, well-maintained facility with up-to-date equipment indicates that the manufacturer takes pride in their work and invests in maintaining a high production standard.

During the visit, note the employees’ expertise and professionalism. Skilled and knowledgeable staff are essential for producing high-quality trailers, and their expertise reflects the overall reliability of the manufacturer.

While many customers have positive experiences with hydraulic modular trailer manufacturers, common issues can arise during the manufacturing and post-purchase phases. Knowing these potential challenges can help you make informed decisions and proactively avoid problems. Here are some of the most common issues faced by customers:

One of the most frequent issues customers encounter is delayed deliveries. Several factors can contribute to delays, including production backlogs, supply chain disruptions, and unforeseen challenges during the manufacturing process.

Manufacturers with high demand or limited production capacity may experience backlogs that extend delivery times. This is particularly common during peak seasons or when the manufacturer handles multiple large orders simultaneously. Customers with time-sensitive projects should communicate their deadlines clearly and confirm the manufacturer’s ability to meet those timelines before placing an order.

The availability of materials and components can also impact delivery schedules. Global supply chain disruptions, such as shortages of raw materials or delays in shipping, can cause unexpected production delays. To mitigate this risk, some manufacturers maintain a stock of critical materials or work with multiple suppliers to ensure a steady supply.

Custom trailers that require specialized components or engineering solutions may take longer to produce than standard models. Custom trailers’ design and testing phases can be time-consuming, leading to longer lead times. Customers should factor in additional time for customization when planning their projects.

Quality control problems can arise if the manufacturer’s processes need to be more rigorous or if there are inconsistencies in materials or artistry.

One common issue is using substandard or defective materials, which can compromise the trailer’s strength, durability, and safety. Manufacturers with solid quality control measures inspect materials upon receipt to ensure they meet the required standards. Customers should inquire about the manufacturer’s material sourcing and inspection processes to minimize the risk of defects.

Inconsistent or poor artistry during assembly can lead to structural weaknesses, misalignments, or functional problems in the trailer. This can affect the trailer’s performance and reliability over time. Manufacturers with skilled and experienced workers are less likely to encounter these issues, so choosing a manufacturer with a reputation for high-quality craftsmanship is essential.

Trailers not thoroughly tested before delivery may have hidden flaws or defects that only become apparent during operation. Comprehensive testing is essential to identify and address issues before the trailer is shipped to the customer. Customers should verify that the manufacturer conducts extensive testing on each trailer to meet all performance and safety standards.

Customers need more after-sales support, especially if problems arise after delivering the trailer.

When issues occur, prompt and practical support is critical to minimizing downtime. Customers who do not receive timely assistance from the manufacturer may experience prolonged interruptions in their operations, leading to lost productivity and revenue. Manufacturers prioritizing customer support typically offer quick response times and have dedicated support teams to address issues as they arise.

Some customers may find that the manufacturer needs to fully address their concerns, leaving them with unresolved issues that affect the trailer’s performance or safety. This can be particularly frustrating if the trailer is still under warranty. To avoid this, customers should choose manufacturers with a strong track record of providing comprehensive and practical after-sales support.

A lack of readily available spare parts can also be a problem, especially if the trailer requires specialized components. Customers needing help to obtain replacement parts quickly may face extended downtime while waiting for the necessary components to be sourced and shipped. Manufacturers with well-established supply chains and spare parts inventories are better equipped to provide the support needed to keep trailers operational.

By being aware of these common issues and addressing them proactively, customers can improve their experience with hydraulic modular trailer manufacturers and ensure that their trailers meet their quality, reliability, and performance expectations.

Before investing significantly in a hydraulic modular trailer, asking critical questions is essential to ensure the manufacturer can meet your specific needs and provide a reliable product. Here are some critical questions to ask:

Customization is often necessary to ensure the trailer meets your specific operational requirements. Ask the manufacturer about the customization options they offer.

Inquire about the manufacturer’s flexibility regarding design modifications. Can they customize the dimensions, load capacity, and hydraulic systems to suit your needs? What options for specialized features such as axle configurations, suspension systems, and braking mechanisms are available?

Ask for examples of previous custom trailers they have built. This can give you a sense of the manufacturer’s experience and capability in delivering tailored solutions. It’s also helpful to understand the process for customization, including timelines and costs.

Understanding the lead time is crucial for planning your project and ensuring the trailer is ready when needed.

Ask the manufacturer about the typical lead time for standard models and custom trailers. How long does it take from order placement to delivery? Could any factors such as material availability or production backlogs extend the lead time?

Inquire about the manufacturer’s track record for meeting delivery deadlines. Can they provide references from previous clients who received their trailers on time? Understanding their commitment to timely delivery can help you manage your project schedule effectively.

Certifications ensure that the trailer meets industry standards and regulatory requirements. Ask the manufacturer about the certifications they hold.

Inquire about certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and any industry-specific safety certifications. These certifications indicate that the manufacturer adheres to high standards in their production processes and that their trailers meet the necessary safety and environmental regulations.

If you plan to use the trailer in different countries, ask about Compliance with regional standards such as CE marking for Europe or DOT regulations in the United States. Ensuring the trailer is certified for use in your target markets is essential for legal operation.

After-sales support is critical for maintaining your trailer’s performance and longevity. Ask the manufacturer about the support services they provide after the sale.

Inquire about the warranty terms, including the duration of coverage and what is included. Does the warranty cover defects in materials and artistry? Are there options for extended warranties?

Ask about the availability of spare parts and how quickly they can be provided if needed. Does the manufacturer keep a stock of commonly used parts? How are parts shipped, and what are the expected delivery times?

Find out what kind of technical support is available. Can you access remote troubleshooting and diagnostic services? Is on-site support offered if needed? Understanding the level of support you can expect will help you manage any issues that arise after the purchase.

Pricing for hydraulic modular trailers is influenced by several factors, each of which contributes to the overall cost of the trailer. Understanding these factors can help you make informed decisions when budgeting for your purchase.

The quality and type of materials used in the trailer construction significantly impact the price.

High-strength steel and aluminum are commonly used in trailer construction. The cost of these materials can fluctuate based on market conditions, availability, and the specific grades required. For example, using premium materials like Q690 steel, known for its superior load-bearing capacity, will typically increase the price of the trailer compared to standard grades.

Suppose the trailer requires specialty materials, such as corrosion-resistant coatings, composites, or advanced hydraulic components. In that case, these can also add to the cost. Manufacturers will factor in the price of sourcing and working with these materials when calculating the final price.

The complexity of the trailer’s design is another critical factor influencing pricing. More complex designs with advanced features generally cost more to produce.

Trailers that require custom engineering solutions, such as unique axle configurations, specialized hydraulic systems, or innovative load-bearing structures, will typically have higher development and production costs. The time and expertise required to design, prototype, and test these custom features are reflected in the price.

Trailers with advanced features, such as automated control systems, real-time load monitoring, or enhanced safety systems, will also command higher prices. These features often require sophisticated technology and additional components, which increase the overall cost of the trailer.

Customizing a trailer to fit unique operational needs, such as specific dimensions, load capacities, or environmental conditions, involves additional design and engineering work. The manufacturer must allocate resources to develop these tailored solutions, which adds to the cost.

Custom trailers may require adjustments to the production process, such as specialized tooling, different assembly methods, or additional testing. These adjustments can increase production costs, passed on to the customer as a higher purchase price.

For highly customized trailers, manufacturers may need to develop prototypes to test and refine the design before full-scale production. The costs associated with prototyping, including materials, labor, and testing, are typically included in the final price.

By understanding these pricing factors, you can better evaluate the cost of a hydraulic modular trailer and make informed decisions about your purchase. Discussing these factors with the manufacturer can also help you explore options that balance your budget with your desired features and performance.

Shipping hydraulic modular trailers internationally is a complex process that requires careful planning, attention to regulatory Compliance, and efficient logistics coordination. These trailers are often large, heavy, and valuable, making it essential for manufacturers to ensure they are safely transported and arrive at their destination in perfect condition. Here’s how manufacturers manage the challenges of international shipping and export:

Compliance with international shipping and export regulations is crucial to avoid delays, legal issues, and potential fines. Manufacturers must ensure that all aspects of the shipment meet the rules of exporting and importing countries.

The first step in ensuring Compliance is to prepare all necessary export documentation. This includes commercial invoices, packing lists, certificates of origin, and any required export licenses. Accurate and complete documentation is essential for clearing customs and avoiding delays at the port of entry. Manufacturers often work closely with customs brokers to ensure that all paperwork is in order and that the shipment complies with international trade regulations.

In addition to export requirements, manufacturers must comply with the destination country’s import regulations. These can include specific requirements for trailer dimensions, safety standards, and environmental regulations. Manufacturers must know these requirements and ensure the trailers meet all necessary standards before shipping. This may involve obtaining additional certifications or modifications to the trailer design to meet local regulations.