What is a Hydraulic Modular Trailer? – Learn Hydraulic Modular Trailers Specs & Accessories

Table of Contents

Introduction

Truth be told, I’m not an expert in hydraulic modular trailers, Therefore, I dedicated a week to research and consult with our engineers for 12 hours, combining this with my decade of sales experience to create this article to share with you, I hope it provides you with some assistance.

In this comprehensive article, we’ll dive into the technical specifications, innovative designs, versatile applications of hydraulic modular trailers, their components, and various combination possibilities. Moreover, we’ll give some useful tips to guide you in choosing the best hydraulic modular and reliable supplier. Okay, Let’s begin!

Chapter 1: What is a Hydraulic Modular Trailer(HMT)?

Have you ever wondered what a Hydraulic Modular Trailer (HMT) is? Simply, it’s a special platform trailer unit used for transporting oversized and heavy loads that are difficult to disassemble and overweight. it’s also called a modular transporter, hydraulic platform trailer or a hydraulic multi-axle trailer.

Their key features include swing axles, hydraulic suspension, independently steerable axles, and the capacity for longitudinal and lateral connections across multiple units. Hydraulic Modular trailers are constructed with high-tensile strength steel, these trailers are engineered to support the substantial weight of diverse cargoes, ranging from oil rig modules and bridge components to entire buildings, ship sections, industrial machinery, and even military hardware like tanks.

Hydraulic modular trailers are multifunctional, they can be configured in various combinations, with some models boasting self-propulsion. Equipped with advanced hydraulic systems for steering, suspension, and lifting, alongside an array of accessories tailored for different transportation requirements, HMTs represent the pinnacle of heavy-duty modular transport.

Chapter 2: Heavy-Duty Modular Hydraulic Platforms Applications

Hydraulic modular trailers can be used for transporting more types of cargo than you can imagine, but of course, it’s a waste to use them to transport lighter cargo, they are mainly used for transporting oversized and heavy-duty loads, Below are some of their key applications you should know.

Construction industry:

These trailers are used for transporting large construction machinery and materials, such as excavators, cranes, and concrete beams that are too large to load and transport on a normal semi-trailer.

Wind Power Industry:

They are used for transporting large rotor windmill turbine blades, wind tower sections, and nacelle in wind energy generation.

Power Stations, Chemical, Iron and Steel Industries:

Modular trailers are used in these industries for transporting large and heavy equipment, such as generators, transformers, turbines, chemical tanks/pipelines,s and other industrial machinery.

Offshore Industry:

Modular trailers are used in the offshore industry for handling heavy equipment and large metallic structures. They are also used for transporting ship sections to assembly halls and the entire ship to the sea.

Bridge Construction:

Hydraulic modular trailers are used to carry large bridge elements and large girders. some of these trailers are connected to crane arms that transport the bridge segments and massive girder sections from the transporter to the road section.

Military:

Many militaries use hydraulic modular trailers for tank transportation, space shuttles, and other heavy-duty applications.

Of course! the hydraulic modular trailers can be used for different transport missions if you change the configurations and combination of modular trailers.

Chapter 3: The Specs and Designs of Hydraulic Modular Trailers

Chapter 3: The Specs and Designs of Hydraulic Modular Trailers

The technical specifications and dimensions of hydraulic modular trailers vary based on the specific model and manufacturer. But there are some common features and specifications I can share with you now.

3.1 Platform Length, Width, and Height:

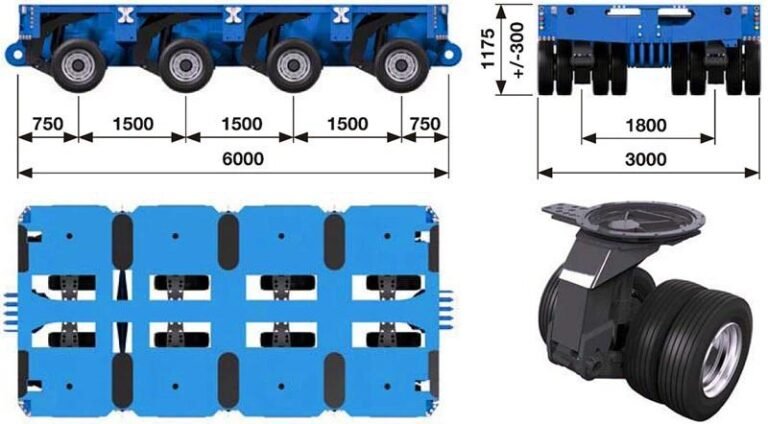

The platform length varies according to how many axles you choose, for example, the length of a 4-axis HPG1 is 6000m. The platform width can range from 2,990mm to 3400mm, and even 4000mm for some special purpose. The platform height can range from 680mm to 1175mm±300mm suspension stroke to accommodate uneven road surfaces.

3.2 Axle Configuration:

For the HMT’s axle, you can choose 2 axles, 3 axles, 4 axles, 5 axles, 6 axles, 8 axles, and 10 axles or even more axle lines to transport different load sizes and weights.

3.3 Loading Weight:

CHINA HIPOTRUK modular trailers can handle up to 45 tons per axle line, the same as the German model trailer. So, the total weight capacity of a hydraulic modular trailer can be calculated based on how many axles of modular trailer you have. For example, a hydraulic modular trailer with 10 axles could potentially carry up to 400 to 450 tons

3.4 Steering Angle:

The steering angle of hydraulic modular trailers can range from 45° to 55°, depending on the specific configuration and manufacturer.

3.5 Steering Mechanisms:

You can choose self-steering or manual control for axle steering. In self-steering, that’s the gooseneck or truck’s drawbar sends a signal to start steering the axles simultaneously. Manual control, which uses a remote control or valve to control the steering axles.

3.6 Hydraulic Power Pack:

This is a diesel engine, Hatz / Kohler Engine brand, typically around 22KW, which is mainly used for steering and lifting the axles.

3.7 STZ-V Gooseneck:

The STZ-V gooseneck, upon receiving steering signals from the tractor truck, synchronizes the steering of the axles and also allows for transferring the load from the axle lines to the gooseneck.

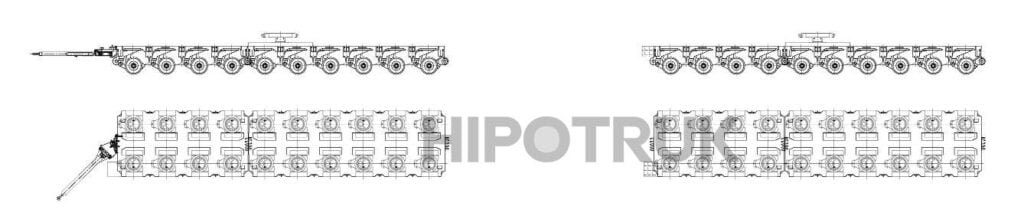

3.8 Combination System:

HMTs can be allowed for end-to-end and side-by-side combinations of each module to complete different transport tasks.

3.9 Braking System:

These trailers are normally equipped with a compressed air brake system, including double brake chambers, WABCO relay valves, and ABS for safe operation. but please note that not all suppliers can use WABCO and ABS, to save cost, some suppliers would choose normal accessories to replace them, but you know it will reduce driving safety.

3.10 Main Technical Specifications: HIPG1 Modular Trailer

| Model | HPG1 | |||

| Axle quantity | 4 | |||

| Speed (km/h) | 0.5 | 5 | 40 | 80 |

| Total weight (t) | 180.0 | 146.6 | 80 | 65.6 |

| Rated load capacity (t) | 166.14 | 132.5 | 66.14 | 51.74 |

| Axle load (t) | 45.0 | 36.6 | 20.0 | 16.4 |

| Length (mm) | 6000 | |||

| Width (mm) | 2990 | |||

| Height(mm) | 1175±300 | |||

| Hydraulic power pack | KOHLER, USA | |||

| Operation | Cable remote control & Radio remote control | |||

| Wheelbase(mm) | 1500, 1800, 2450 | |||

| Tread (mm) | 1800/735 | |||

| Tire | 215/75R17.5, 135/133J 16PR | |||

| Tire quantity | 32 | |||

| Steering angle | ±55° | |||

| Turning radius | ≤2550 (inside), ≤7500 (outside) | |||

| Working temperature | -40℃~+55℃ | |||

| Drawbar | 2 m, 3 m and 5 m | |||

Chapter 4: The Main Components of a Hydraulic Modular Trailer

To be honest, the hydraulic modular trailer is complicated machinery, don’t worry, let’s delve into the main components of the hydraulic modular trailer

4.1 Frame:

The heart of the modular trailer, its frame, including the longitudinal girder, bogie frame, and steering arm. It’s box-type carrying beam structure, is often made of high-strength steel to provide strength and stability.

4.2 Hydraulic Wheel Bogie:

Hydraulic Wheel Bogie: At the core of the trailer’s mobility is the hydraulic wheel bogie, which consists of the bogie frame, hydraulic cylinder, axle, tire, and rocker arm. It ensures even load distribution and adapts to uneven terrains, maintaining stability and strength under varying conditions.

4.3 Steering System:

There are two types of wheel bogie steering systems used in HMTs: the ball bearing race ring and pivot bearing make the modular trailer achieve 45-55 degree turning angle.

Ball Bearing Race Ring Steering: Ideal for off-road operations, trailers with this steering system are designed to navigate and bear heavy loads in challenging site conditions.

Pivot Bearing System: Tailored for heavy-duty on-road transport, this system features reinforced frames for maximum axle load handling, making it perfect for in-plant operations.

4.4 Hydraulic System

The hydraulic system, including pumps and cylinders, plays a crucial role in controlling driving speed and steering power. Hydraulic cylinders in the transporter have anti-block valves for safety in case of pipeline breakage.

4.5 Lifting System:

The modular unit’s platform can lift up to 600mm, offering ±300mm axial load compensation to accommodate uneven road surfaces.

4.6 Brake System

Equipped with a compressed air brake system, including double brake chambers, single brake chambers, WABCO relay valves, and ABS, brake drums, and reservoirs for safe and reliable braking

4.7 Combination System

HMTs can be combined side-by-side or end-by-end, and they use a hydraulic link-pin to combine modular units end-by-end. The combination system is essential for adapting the trailer to different transport tasks

4.8 Power Pack:

The hydraulic power pack is essential for powering the hydraulic systems of the trailer and control devices in modular transports perform various functions, including steering and vehicle combination adjustments. Although different from the PPU in function and performance, the power pack efficiently steers the modular trailer, though it lacks the power to drive the axles.

4.9 STZ-V Gooseneck

The STZ-V gooseneck, upon receiving steering signals from the tractor truck, synchronizes the steering of the axles. Its lifting function adapts to the cargo platform’s height.

This gooseneck also shares the cargo weight, enhancing the vehicle’s traction without adding extra weight to the truck tractor. Its steering cylinders service both the front and rear systems of the trailer, with adjustable coupling height and clearance to fit most truck tractors.

4.10 Electric System

The modular trailer’s electric system features a 24 V power pack and an LCD color monitor for electronic monitoring and control. The micro control system with a CAN bus ensures stable, reliable data transmission, displaying critical information like speed, temperature, and pressure, complete with alarm indicators.

Chapter 5: Accessories for Hydraulic Modular Trailers

Sometime in order to complete a transportation task or transport some special equipment, you have to assemble some accessories on your modular trailer, just like after you buy a mobile phone, if you want to play some game, you have to install some apps first. Okay, let’s how many accessories you can choose for your HMTs.

5.1 Towing Equipment:

This category includes drawbars, available in lengths ranging from 2m to 5m, tailored for various towing needs. Additionally, steering swivel arms for single-width setups and center pulling devices for parallel (1 + 1/2) and side-by-side (1 + 1) combinations are available, enhancing the trailer’s adaptability.

5.2 Hydraulic STZ-V Goosenecks:

Hydraulic goosenecks are crucial for connecting the trailer to the towing vehicle. They offer adjustable weight distribution for optimal balance and steering synchronization. Notably, these goosenecks also have a lifting function for height adaptability and can partially bear the cargo weight, serving as a superior alternative to traditional drawbar equipment.

5.3 Loading Equipment:

The loading equipment of the hydraulic modular trailer includes drop deck beds, vessel bridges, intermediate spacers, excavator decks, extendable spacers or telescopic beams, and turntables.

Drop Deck:

This drop deck has a low center of gravity for safe transport conditions, because a beam construction height down to 250mm, is very suitable for transporting transformers if there are height restrictions, such as under bridges or power lines. The coupling heads are firmly welded to the deck or there is alternatively an over-drivable hook system with a quick coupling device.

Vessel Bridge:

Ideal for transporting higher and wider abnormal tanks vessels and other equipment; The length and width of the bridges can be adjustable, and extendable to accommodate various equipment sizes.

Intermediate spacer:

Known as a connection platform, these spacers link multiple trailer modules to extend the overall length, particularly beneficial for long yet relatively light loads.

Extendable spacers,

also known as telescopic beams, are key accessories for hydraulic modular trailers. They are designed to increase the length of the trailer, allowing it to carry longer loads.

Excavator deck:

Excavator decks on hydraulic modular trailers are specialized loading platforms designed to accommodate and transport excavators and other types of heavy construction machinery.

Turntables (bolster):

Turntables are available for the transport of long and heavy loads, such as concrete bridges, tanks, and large girders, The front turntable is a purely mechanical system, and the rear turntable is generally equipped with a hydraulic self-tracking device to steer the rear dolly automatically.

Blade Lifter (Wind Blade Adapter):

The Blade Lifter, or wind blade adapter, is ingeniously designed for transporting wind turbine blades, especially in challenging mountainous areas. Integrated with a hydraulic modular trailer or SPMT module, this system’s advanced hydraulic cylinder control and slew bearing enable the blade to tilt up to 60 degrees. This capability is vital for safely maneuvering around obstacles like trees, cliffs, buildings, and power lines, ensuring the secure and efficient transport of these colossal blades.

Wind Tower Adapter:

Specifically crafted for moving windmill tower segments, the Wind Tower Adapter is a cornerstone in wind turbine logistics. When paired with hydraulic multi-axle modular trailers, it adeptly manages tower segments up to 150 tons and 6500mm in diameter. This adapter plays a critical role in the secure and stable transportation of these significant turbine components.

Girder Frame:

At the heart of the girder bridge trailer lies the Girder Frame, strategically placed on both the front and rear transport modules to support heavy loads. The load is “hoisted” by the frame and distributed evenly to the multi-axle transport modules at both ends, ensuring balanced load sharing. With no wheel restrictions beneath the frame, the overall transportation height can be significantly reduced, even to ground level, which is advantageous for height-sensitive transports. The girder bridge trailer offers not only ease and safety in loading and unloading but also independence from additional lifting equipment for some models. Moreover, the flexible steering structure of the split-type transporter facilitates effortless navigation, even in tight corners and with long vehicle lengths.

Chapter 6: Combination Forms of a Modular Trailer

The versatile hydraulic modular trailer offers three distinct towing configurations, made possible through various combinations of accessories and support equipment. These configurations allow for flexibility in transportation, including options such as a semi-trailer, a standard trailer, and a self-propelled trailer. Here’s how each setup comes together:

Drawbar Combination: This setup connects the drawbar, the main body of the trailer, and the lateral steering frame, providing a robust option for varied towing needs.

STZ-V Gooseneck Combination: Incorporating the STZ-V gooseneck with the trailer’s main body enhances its functionality, allowing for more complex hauling tasks.

Self-Towing Configuration: By integrating the PPU device with module units and self-propelled modules, the trailer gains autonomy. This setup includes a power unit that supports hydraulic movement, an air brake system, a lifting mechanism, and steering capabilities.

This innovative modular trailer can entirely replace traditional vehicles for specific tasks, especially in transporting heavy loads at speeds under 5km/h. Each combination offers unique advantages tailored to different hauling requirements, showcasing the modular trailer’s adaptability and efficiency in heavy transportation.

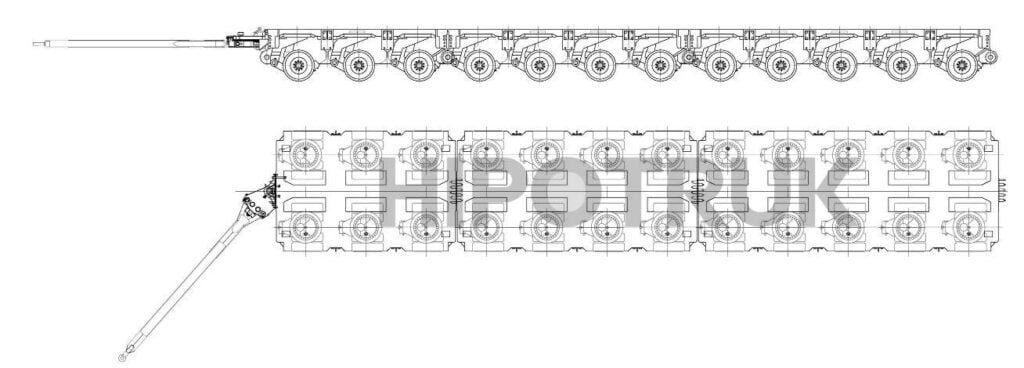

6.1 Combination with drawbar

This modular approach offers a range of configurations across different series, including the 2-file, 3-file, and 4-file combination with a drawbar. The primary distinction among these setups lies in the specific accessories utilized. Here’s a closer look at each configuration:

2-file combination with drawbar

This combination includes the drawbar, a power pack, a modular unit, a side steering frame, and additional combination accessories. The choice of the modular unit is determined by the cargo type, with options extending up to 32 axle lines. Additional equipment, like a flat beam or a low flat beam, can complement the 2-file drawbar setup for enhanced versatility.

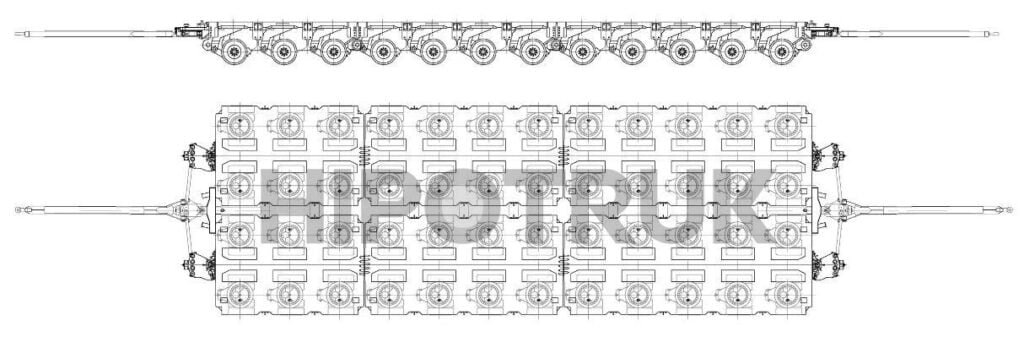

3-file combination with drawbar

Featuring the drawbar, power pack, side steering frame, a modular unit, combination accessories, a half modular unit, and one or two central steering frames, the 3-file configuration offers an upgraded capability compared to the 2-file setup. The inclusion of half modular units and central steering frames adds to its functionality and adaptability.

4-file combination with drawbar

This configuration is composed of a drawbar, power pack, one or more central steering frames, a modular or half modular unit, a side steering frame, and the necessary combination accessories. It represents the most comprehensive option among the drawbar setups, suitable for the most demanding transportation needs.

All drawbar configurations allow for modular units with up to 32 axle lines, catering to a broad range of transportation requirements and ensuring flexibility and efficiency in heavy load movement.

6.2 Combination form of the turntable

The turntable setup introduces a highly flexible combination for modular transport, featuring a drawbar, a turntable mechanism, a modular unit, a power pack, a side steering frame, and assorted combination accessories.

The key element, the turntable, stands out for its ability to be used in tandem, especially when the task involves transporting extra-long items. This innovative approach ensures smooth and efficient handling of oversized loads by providing additional rotational maneuverability.

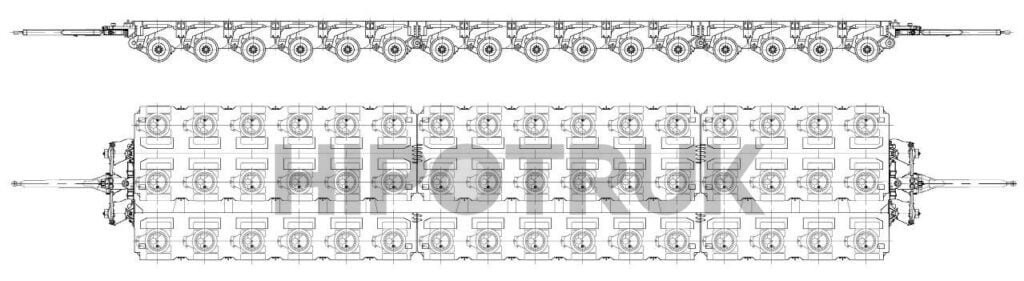

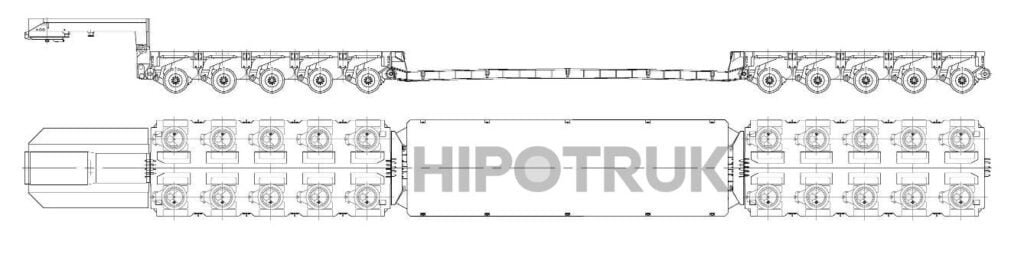

6.3 Combination with STZ-V gooseneck

This particular arrangement incorporates the STZ-V gooseneck, either a full or half modular unit, a power pack, and various combination accessories to create a versatile hauling solution.

Designed to support up to 16 axle lines, this combination allows for the selection of an appropriate modular unit tailored to the specific requirements of the cargo. While this setup excels in numerous transport scenarios, its configuration is not ideally suited for carrying over-length goods. However, the inclusion of auxiliary equipment, such as a flat beam, can enhance its utility, making it a valuable option for a wide range of transportation needs.

Chapter 7: Top Hydraulic Modular Trailer Manufacturers in the World

In fact, there are not many manufacturers that can produce high quality hydraulic modular trailer in the world. now, please let me introduce the top 7 manufacturers.

Hipotruk- Leading Manufacturer of HMT in China.

Hipotruk is a Chinese company in the field of heavy transport manufacturing. Their HMT can combine with Geraman modular trailers, PST, Kamag 25, Nicolas MDE/MDED, Self propelled modular transporter SPT,SPMT,PST,PST-E andScheuerle modular trailer etc.

HIPO Hydraulic modular trailers are known for their superior quality and advanced technology, rivaling European counterparts in functionality. The most important is the price of the HIPO hydraulic modular trailer is only about one-third of the European manufacturer’s product. Hipotruk’s market reach is global, with a significant presence in European, American, South American, Asian, and African markets.

Goldhofer – Leading Manufacturer of Hydraulic Modular Trailers

Goldhofer is an internationally renowned manufacturer of intelligent and exceptional transport solutions. With a history dating back to 1705, the company has evolved to become a leading player in the industry. Their vehicles are designed for both on-road and off-road heavy-duty haulage, airport operations, and carrying oversized cargo. Operating on a 100,000 sq. meter premises, Goldhofer prides itself on producing high-quality products. They offer a wide range of heavy-duty modules, trailers, and semi-trailers suitable for various transportation needs, including moving heavy cargo in airports.

Scheuerle – Leading Production Site for Transporters in the TII Group

Scheuerle is considered the largest production site of transporters in the TII Group, a conglomerate that includes Kamag Transporttechnik, Nicolas Industrie, Scheuerle, and Tratec. Specializing in building heavy-duty vehicles for road transportation, Scheuerle stands out for its use of pendulum axles controlled through hydraulics. With a manufacturing and testing facility spanning 70,000 sq. meters, Scheuerle offers vehicles for road transportation, compact automobiles, power boosters, self-propelled modular trailers, and self-propelled transporters. Its rich history, combined with technology and experience from four companies within the TII Group, positions Scheuerle as an industry leader.

Nicolas – Experienced Manufacturer of Specialized Heavy-Duty Vehicles

Nicolas, another key member of the TII Group, has established itself as a specialist in providing heavy-duty vehicles, including self-propelled modular trailers. The company offers compact and modular vehicles for special transporters and road transport. With decades of experience, Nicolas has built a solid reputation for developing modular trailers that cater to the needs of transporting heavy cargo. They provide customized solutions for various industries, such as mining, wind energy, air and space, and more. Nicolas brings a wealth of experience to the table, with a history dating back to 1855 and continuous quality improvement.

Kamag – Trusted Manufacturer of Heavy-Duty Vehicles

Kamag, a part of the TII Group, is located in Ulm and has a rich history of manufacturing heavy-duty vehicles. With over 300 employees and a 45,000 sq. meter premises, Kamag specializes in producing modular transporters, terminal logistics vehicles, and industrial vehicles. Their product range includes special transporters, power boosters, and shipyard transporters. Kamag has earned a loyal customer base due to its reliability, efficiency, and quality customer service. They also offer solutions for the air and space industry, as well as the metal industry.

Cometto – Renowned Manufacturer for Heavy-Duty Vehicles

Cometto is a widely recognized manufacturer known for its electronic modular self-propelled vehicles, heavy-duty trailers, heavy modular trailers, and special self-propelled trailers. Their products have found applications in various industries, including the steel industry, construction, heavy haulage, aerospace, wind energy, offshore platforms, oil and gas, and shipbuilding. Founded in 1954, Cometto has expanded over the years through mergers and acquisitions. They offer modular transporters with different power pack units, allowing customers to choose between diesel and hybrid options based on their needs.

Faymonville – Reliable Manufacturer of Hydraulic Transport Modules

Faymonville is well-known for its ModulMAX series, which features combinable transport modules with 2-6 axle lines suitable for both off-road and on-road operations. Their trailers offer a variety of options and accessories to accommodate different types of loads. With innovative technology like pendle-axle technology, Faymonville trailers can operate in multiple modes, including Trailer Mode, Assist-Propelled Mode, and Self-Propelled Mode.

When it comes to hydraulic modular trailers, it is crucial to choose a reputable and reliable manufacturer. The featured manufacturers – Hipotruk, Goldhofer, Kamag, Cometto, Scheuerle, Nicolas, and Faymonville – have established themselves as leaders in the industry. Each company offers unique products and solutions tailored to various transportation needs. By considering factors such as quality, durability, and customer reviews, you can make an informed decision and choose the best hydraulic modular trailer manufacturer that suits your requirements.

Chapter 8: Ultimate Hydraulic Modular Trailer Buying Guide

I believe you may know how to buy the best hydraulic modular trailer if you have used hydraulic modular trailers for many years, below are some considering factors for your reference.

8.1 Understanding the Specifications:

Firstly, you need to understand the common specifications of the hydraulic modular trailer, such as the load capacity, and trailer’s dimensions ( including the length, width, and height). For instance, the HIPOTRUK HPG1 offers a wide range of variations and accessories, with axle loads of up to 45 tons at 1 km/h, a dead weight of 13.85 tons for a 4-axle module, and a maximum steering angle of ± 55°. On the other hand, the Nicolas MDE/MDED Modular Trailer can handle up to 34 tons of technical axle load, has a suspension stroke of 600 mm, and a steering angle of up to 55°.

For the load capacity, you should know the weight of equipment you will transport, so that you can choose the right hydraulic modular trailer to handle your specific load requirements.

8.2 Choose the Right Type of Modular Trailer

There are some specific features of the hydraulic systems in German Hydraulic Modular, HIPOTRUK HPG1 and Nicolar MDE/MDED hydraulic modular trailers you should know.

The HIPOTRUK HPG1 hydraulic modular trailer’s loading capacity is 45 tons at 5 km/h, a dead weight (for a 4-axle unit) of 13.85 tons, axle compensation of 600 mm, and a maximum steering angle of ±55°. HIPOTRUK HPG1 model steering system adopts Ball Bearing Race Ring Steering, which is more suitable for off-road operations.

Nicolas MDE/MDED hydraulic modular trailers’ loading capacity is about 22 tons at 5 km/h and a maximum steering angle of ±55°. Nicolas MDE/MDED model steering system adopts pivot Bearing Steering, which is more suitable for in-plant operations.

8.3 Choose the Right Combination

The combination forms of modular trailers are very important because the one form of a modular trailer can’t help to handle various types of cargo, some cargo may be too high, some may be too long or wide, or too heavy. therefore, your modular trailer has to combine with some accessories to become a Superman to handle different kinds of cargo for you. Below are some common combination forms and accessories for you.

- Combination with STZ-V Gooseneck: The hydraulic gooseneck connects the trailer to the tractor truck, helping to balance the load and make steering easier. It can lift up for height changes and helps carry part of the cargo’s weight, making it better than old-style towing equipment.

- Combination with Drawbar: It’s common for the drawbar to combine with the trailer. It allows for the transportation of overweight goods at speeds below 5km/h

- Combination with Drop Deck: The drop deck is low to the ground, and good for carrying tall items like transformers under bridges or power lines. It’s attached firmly to the trailer and can quickly connect to other parts.

- Combination with Vessel Bridge: Great for moving big, tall tanks, subway train units, or equipment. Its size can change to fit different loads.

- Combination with Intermediate Spacer: These spacers lengthen the trailer, useful for carrying long but not too heavy items.

- Combination with Extendable Spacer: Known as telescopic beams, these parts make the trailer longer for carrying longer items.

- Combination with Excavator Deck: This is a special platform on the trailer for carrying big construction machines like excavators

- Turntable (Bolster) Combination: Used for very long and heavy loads. The front part is mechanical, and the back part moves on its own to help steer the trailer.

8.4 Visit Manufacturers:

if possible, you can try to visit your potential manufacturers, to check the quality of their products in person, and visit their production workshop and manufacturing process. And it would be a good time to negotiate with your suppliers face-to-face to get a better price and delivery time.

8.5 Quality and Performance Testing:

Almost all suppliers would say that their hydraulic modular trailer will be tested before being delivered to customers. but actually, not all of them have corresponding testing equipment or measures to test the products.

For example, Before shipping our Hipo modular trailer, we make sure to thoroughly test them at our factory. This includes driving our trailer for more than 7 days to assess its quality and performance. Key checks include ensuring there are no steering axle errors, no unusual sounds during operations, and no oil leak problems. what’s more, we put heavy stones on the trailers to test whether they can meet customer’s specific load requirements. Therefore, you should check whether your supplier’s quality control measures meet China’s quality and safety standards.

8.6 Budget Considerations

It’s important to balance between the quality and price of the product. It’s a common understanding that extremely low prices can indicate lower quality. This is especially true in the Chinese market, where it’s hard to judge a product’s quality just by its appearance.

If you find a supplier offering prices 20% lower than the market’s lowest, be careful. Low prices can lead to poor quality, and sometimes even scams, so you’d better go to the factory to check their product first before making the purchase. Remember, in business, the cheapest option can often mean higher costs in the long run due to repairs, maintenance, or the need to replace the product entirely.

My advice is to adjust your budget to prioritize product quality. It’s better to invest a bit more upfront than to face continuous problems later. Remember, you know we usually get what we pay for.

8.7 Find a Reputable supplier:

Working with a reputable supplier will help you understand the difference between modular trailer types and their features, and recommend the best model for you.

8.8 Warranty:

Consider the warranty and customer support offered by the manufacturer. Make sure to choose a trailer from a reputable manufacturer that offers a warranty and customer support that meets your needs.

Conclusion:

It is an important investment to buy the best hydraulic modular trailer for your job, if you can buy the right one, it will serve you well for years to come. Buying a China hydraulic modular trailer to combine with your hydraulic modular trailer can be a cost-effective option for you at present. Because the price of Chinese products is only one-third of the price of European products.

We warmly invite you to visit HIPOTRUK. Seeing is believing, and by visiting us, you’ll get a true sense of our manufacturing capabilities and experience. You’ll see our multiple production lines, advanced machinery, and quality inspection equipment. Plus, you’ll meet our professional service team and discuss your requirements directly with our technical engineers. This visit could lead to quicker solutions, better pricing, and improved delivery times. We understand it’s a significant journey to visit us, indicating your serious intent to purchase.

Get a Quote

Contact us 24×7 to answer your questions and requirements.

Need more help?

Contact us 24×7 to answer your questions and requirements.

+86 13864095913

+86 13864095913